Hes

- 4

- 0

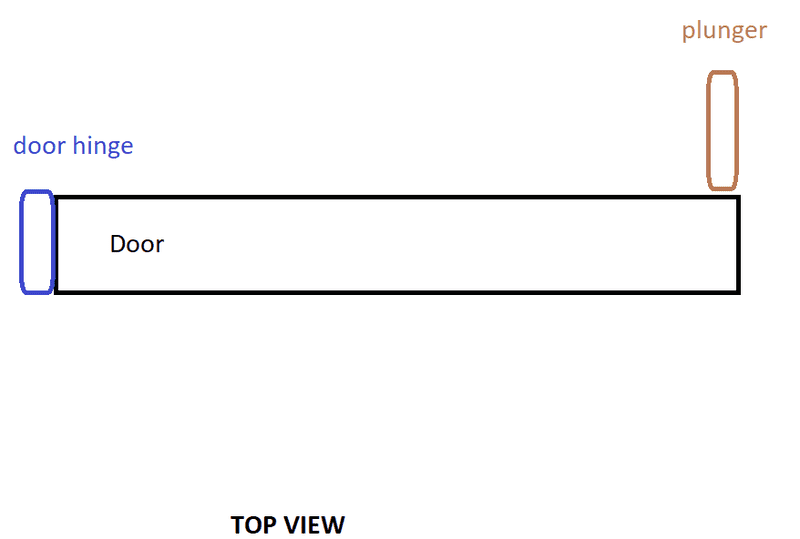

I have this door that was designed to supposedly open for 180 degrees in 1 second. A Pneumatic Plunger was used to push the door. However I'm not sure if this was strong enough to open the door. Can this be counted as Partially Inelastic Collision?

DOOR:

m = 136pound

width = 40 inch

height = 80in

PLUNGER:

Working Pressure = 80psi

Bore Size = 1.5 inch

Stroke Size = 2 inch

Max speed = 6.4in/s

m = 1 lb

DOOR:

m = 136pound

width = 40 inch

height = 80in

PLUNGER:

Working Pressure = 80psi

Bore Size = 1.5 inch

Stroke Size = 2 inch

Max speed = 6.4in/s

m = 1 lb