thorq

- 9

- 0

Hello guys,

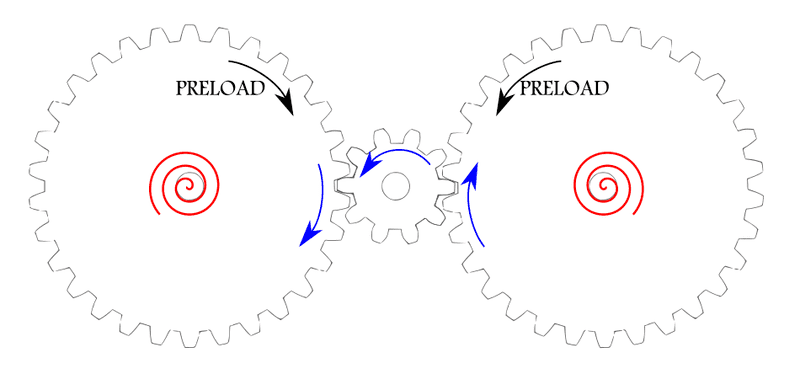

I am quite unsure if this application I have will be zero backlash using the solution in the attached image. I don't really have any means to test this so asking around sounds like a good feedback chance.

I haven't decided yet on the preloading solution but it will be done so that both driven gears will be pushing the motor gear as shown in the img. At this point, when motor stops and starts turning in the other direction, there should be zero time when any driven gear is not engaged by the motor gear's teeth. Or at least this is my theory.

Thanks for your feedback.

I am quite unsure if this application I have will be zero backlash using the solution in the attached image. I don't really have any means to test this so asking around sounds like a good feedback chance.

I haven't decided yet on the preloading solution but it will be done so that both driven gears will be pushing the motor gear as shown in the img. At this point, when motor stops and starts turning in the other direction, there should be zero time when any driven gear is not engaged by the motor gear's teeth. Or at least this is my theory.

Thanks for your feedback.