- #1

adamjts

- 24

- 0

Laser Interferometer--Need advice/opinions about design.

Hey Everyone,

I'm in the midst of designing a laser interferometry system to measure flatness and to level a stainless steel plate. It's a really simple design and I'm wondering what the drawbacks are for this type of system. I'm just in high school my understanding is more limited.

Requirements:

-Must detect a z axis displacement of 10 microns or less

-be able to determine the flatness of a surface to within 10 microns across a 12x12" plate

What I have so far:

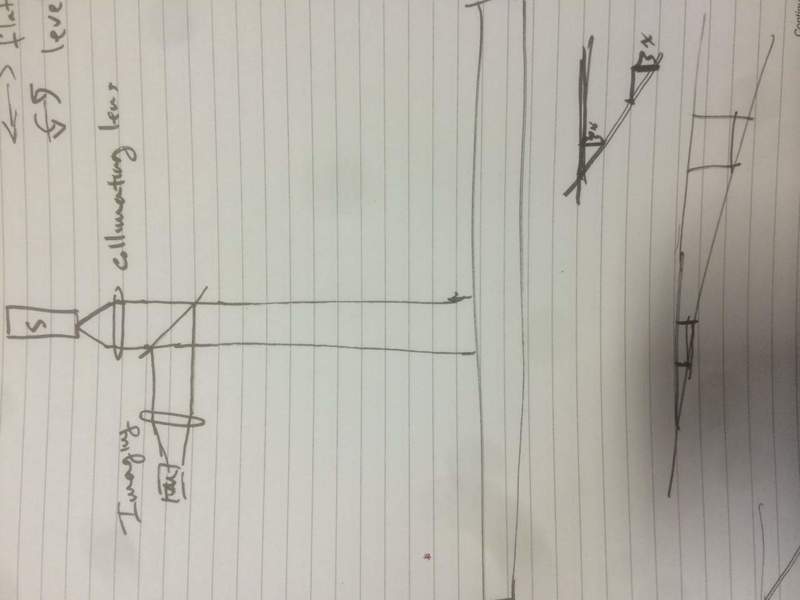

A laser points downward and shines a beam of light through a collimating lens. The lens collimates the beam. The beams of light pass through a beam splitter angled 135° to the horizontal. The beams continue on to reflect off of the stainless steel plate and passes through the beam splitter again. The beams of light then pass through a collimating lens and into the imaging system.

I attached a simple sketch of the design.

I'm wondering:

-How effectively can the system measure flatness by moving laterally.

-How can the system measure how level the plate is. Would the system have to rotate in order to determine how level the plate is?

I'd be extremely grateful if someone could offer some brief feedback and let me know if something doesn't quite look right with this design. THANKS!

Hey Everyone,

I'm in the midst of designing a laser interferometry system to measure flatness and to level a stainless steel plate. It's a really simple design and I'm wondering what the drawbacks are for this type of system. I'm just in high school my understanding is more limited.

Requirements:

-Must detect a z axis displacement of 10 microns or less

-be able to determine the flatness of a surface to within 10 microns across a 12x12" plate

What I have so far:

A laser points downward and shines a beam of light through a collimating lens. The lens collimates the beam. The beams of light pass through a beam splitter angled 135° to the horizontal. The beams continue on to reflect off of the stainless steel plate and passes through the beam splitter again. The beams of light then pass through a collimating lens and into the imaging system.

I attached a simple sketch of the design.

I'm wondering:

-How effectively can the system measure flatness by moving laterally.

-How can the system measure how level the plate is. Would the system have to rotate in order to determine how level the plate is?

I'd be extremely grateful if someone could offer some brief feedback and let me know if something doesn't quite look right with this design. THANKS!

Last edited: