SUMMARY

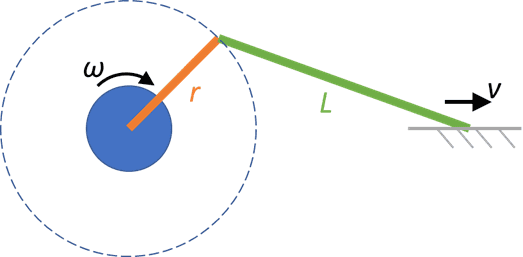

The discussion centers on designing a hydraulic cylinder driven by a step motor, focusing on achieving a constant linear velocity for the piston. Participants clarify that while the piston cannot maintain constant velocity due to its sinusoidal motion, a near-constant flow rate can be targeted for each stroke. Suggestions include using a ball screw or rack and pinion mechanism for better control, while also emphasizing the theoretical impossibility of achieving true constant velocity due to the nature of piston motion. The conversation concludes with practical approaches, such as using a stepper motor to drive a fixed displacement pump.

PREREQUISITES

- Understanding of hydraulic systems and cylinder mechanics

- Familiarity with stepper motors and their control

- Knowledge of kinematics, particularly piston motion equations

- Experience with mechanical design concepts, including ball screws and rack and pinion systems

NEXT STEPS

- Research the kinematics of piston motion and the implications of sinusoidal velocity profiles

- Explore the design and implementation of ball screw mechanisms for hydraulic applications

- Study the operation and control of stepper motors in hydraulic systems

- Investigate fixed displacement pumps and their integration with stepper motors for hydraulic actuation

USEFUL FOR

Mechanical engineers, robotics designers, and anyone involved in hydraulic system design and control will benefit from this discussion, particularly those seeking to optimize the performance of hydraulic cylinders driven by step motors.