Guest312

- 2

- 0

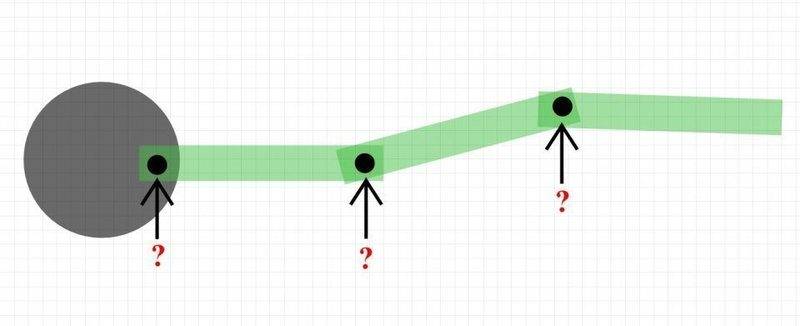

I want to make a simple slider crank mechanism. I don't know what type of bolts or whatever is used for movable arms. I've heard online so far that using a carage bolt and nylon lock nut will work, but I bet there's probably other ways to make a movable joint. Something more secure. I'm sure they don't use Nylon lock nuts with carriage bolts with robotic arms. I want to make a shaker. It's not for school if you can clearly see by my DOB, and profile image.