Thanks. That reference to a SoleAqua QF-HP22 to helps a bit, but not enough.

[Begin mini-rant]

Is it just me, or is product literature becoming abysmally useless?

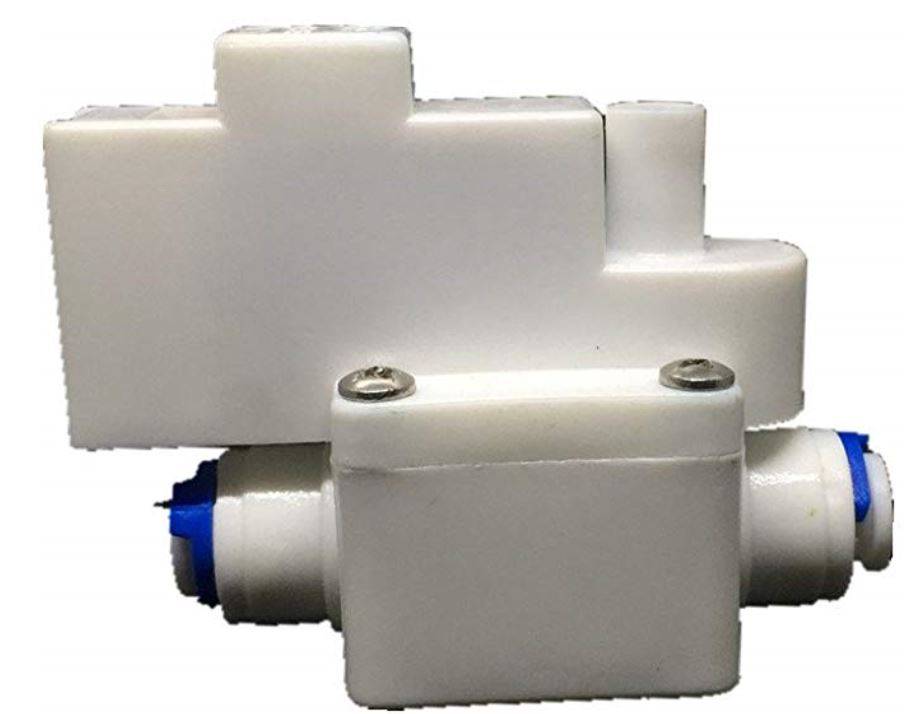

This is the sum total of their specification page.

View attachment 256073

At least it gives a water pressure of 35 to 40 PSI, which I'm assuming is the operating set point adjustment range, but no mention of differential set point, or anything else like allowable temperature range, fluid compatibility, burst pressure, switch data (voltage, current, etc.), or, important to this discussion, an exploded drawing of it's inner workings.

[End mini-rant]

In general, pressure switches have two set points - the operating set point, and "deadband" or "differential" set point (not to be confused with it being a differential switch). The stated 35 to 40 PSI may indicate operating set point adjustment range (when the hex screw is turned all the way counter-clockwise it'll switch at 35 PSI, and switch at 40 PSI when turned completely clockwise), but that's just a guess. The differential set point may also be user-adjustable, but is often set to a fixed value by the manufacturer.

For example, if a pressure switch has an operating set point of 40 PSI and differential ("deadband") set point of 8 PSI, it will open at 40 PSI, and remain open until pressure drops below 32 PSI (40 PSI - 8 PSI, hence, differential).

This link has a basic explanation of differential switch operation, and a rough schematic drawing of it's internals.

https://www.instrumentationtoolbox.com/2012/11/how-differential-pressure-switch-works.html

What are the two ports on your pressure switch connected to? In this marked-up sketch I've assumed one of them are on the outlet side of the UV treatment unit ... where does the other one go to?

View attachment 256076

It may turn out this particular switch simply isn't capable of switching on the UV unit when the faucet is opened. If sensed pressure differential between port A and port B never equals or exceeds 35 PSI, the switch will never actuate to the open position and turn off the UV unit, regardless of screw adjustment.