elixirnova

- 12

- 0

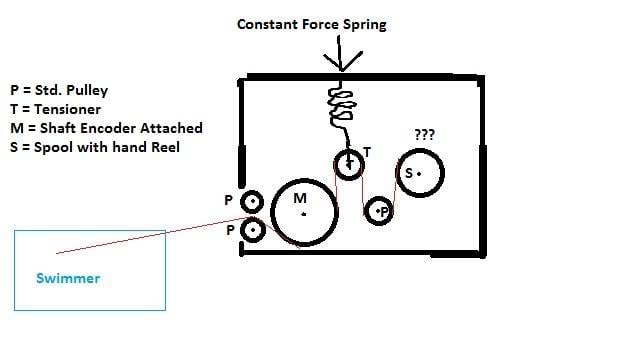

Alright I am trying to measure the "instantaneous" velocity of a swimmer at around 400Hz.

I plan on attaching the swimmer to some nylon rope or something similar and having the rope go into a "box" that will use pulleys, a wheel mounted to a shaft and shaft encoder that will rotate freely between two bearings, and a spool that will feed the line.

My big problem is maintaining tension in the line that is fairly constant and negligible (probably 1lbf or less would be nice), but consistency is most important for testing.

I have found out there are constant force springs out there. So I figure I could attach a pulley to one of those to maintain tension on the line, but with constant tension on the line(which is needed) the line will always be unspooling from the spool faster than it needs to be...

The swimmer's velocity will fluctuate between around 3m/s and 0m/s at the most extreme situation and velocity fluctuations can be expected up to around 10Hz.

Any ideas on how I can make this work?

Here is what I have so far

Also, I tried looking up belt tensioners for car but couldn't find anything to show how they work. Could a belt tensioner help me?

I plan on attaching the swimmer to some nylon rope or something similar and having the rope go into a "box" that will use pulleys, a wheel mounted to a shaft and shaft encoder that will rotate freely between two bearings, and a spool that will feed the line.

My big problem is maintaining tension in the line that is fairly constant and negligible (probably 1lbf or less would be nice), but consistency is most important for testing.

I have found out there are constant force springs out there. So I figure I could attach a pulley to one of those to maintain tension on the line, but with constant tension on the line(which is needed) the line will always be unspooling from the spool faster than it needs to be...

The swimmer's velocity will fluctuate between around 3m/s and 0m/s at the most extreme situation and velocity fluctuations can be expected up to around 10Hz.

Any ideas on how I can make this work?

Here is what I have so far

Also, I tried looking up belt tensioners for car but couldn't find anything to show how they work. Could a belt tensioner help me?