- #1

Paul Nicholson

- 8

- 1

I found this closed thread and I'd like to continue it: https://www.physicsforums.com/threads/design-question-wiring-motors.459672/

I am building a rotating ceiling mount (or rotating a floor plate) and am trying to solve the problem of the continuous rotation servo motor getting in the way of the wires that need to pass through. This would be exactly the same issue as placing flashing LEDs on fan blades - how can it be done easily and cheaply with links to the parts I need?

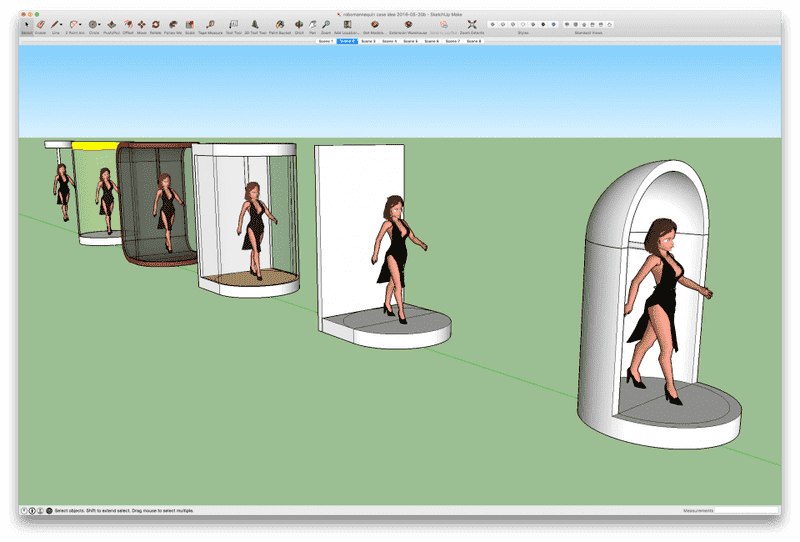

Hollow core pancake slip rings seem like the logical way to accomplish the task of running wires from a rotating base to a stationary robot. Please see my design. But they are very expensive. I am developing a product and need to find a reliable store that sells exactly what I need. This is a minor detail of the robot so I would rather the entire mechanical design already exists and I can simply buy it. Engineers and fabricators cost a lot.

My second idea for how to run wires through a rotating shaft is to put the motor to the side of a hollow artificial shaft and let the wires run freely while using a belt, although this would still result in a twisted wire, and is extremely difficult and time consuming to build with a tensioner spring and all the rest of the measuring efforts to find suitable belts and pulleys etcetera. I really do want the robot to be able to rotate continuously in the same direction as long as it needs to for clothing fashion windows. Rotating 180 degrees is as easy as providing some wire slack, but this would not be desirable.

I am not after concepts (unless they are different from the two I mentioned above), but rather the exact parts I need to build a rotating system to attach to my motor, or a completely intact mechanical system I could easily buy for less than $100. The last thing I want is to spend thousands of dollars on Research and Development for this considerably simple task. A hollow core slip disc that allows for at least 50 Amps and a couple of data lines for less than $100 would be the best, I think.

Thanks in advance for any product links or steering column modification ideas, new concepts etc you can provide.

I am building a rotating ceiling mount (or rotating a floor plate) and am trying to solve the problem of the continuous rotation servo motor getting in the way of the wires that need to pass through. This would be exactly the same issue as placing flashing LEDs on fan blades - how can it be done easily and cheaply with links to the parts I need?

Hollow core pancake slip rings seem like the logical way to accomplish the task of running wires from a rotating base to a stationary robot. Please see my design. But they are very expensive. I am developing a product and need to find a reliable store that sells exactly what I need. This is a minor detail of the robot so I would rather the entire mechanical design already exists and I can simply buy it. Engineers and fabricators cost a lot.

My second idea for how to run wires through a rotating shaft is to put the motor to the side of a hollow artificial shaft and let the wires run freely while using a belt, although this would still result in a twisted wire, and is extremely difficult and time consuming to build with a tensioner spring and all the rest of the measuring efforts to find suitable belts and pulleys etcetera. I really do want the robot to be able to rotate continuously in the same direction as long as it needs to for clothing fashion windows. Rotating 180 degrees is as easy as providing some wire slack, but this would not be desirable.

I am not after concepts (unless they are different from the two I mentioned above), but rather the exact parts I need to build a rotating system to attach to my motor, or a completely intact mechanical system I could easily buy for less than $100. The last thing I want is to spend thousands of dollars on Research and Development for this considerably simple task. A hollow core slip disc that allows for at least 50 Amps and a couple of data lines for less than $100 would be the best, I think.

Thanks in advance for any product links or steering column modification ideas, new concepts etc you can provide.