aero1965

- 1

- 0

Hi y'alllll!

Need some guidance on a little issue,

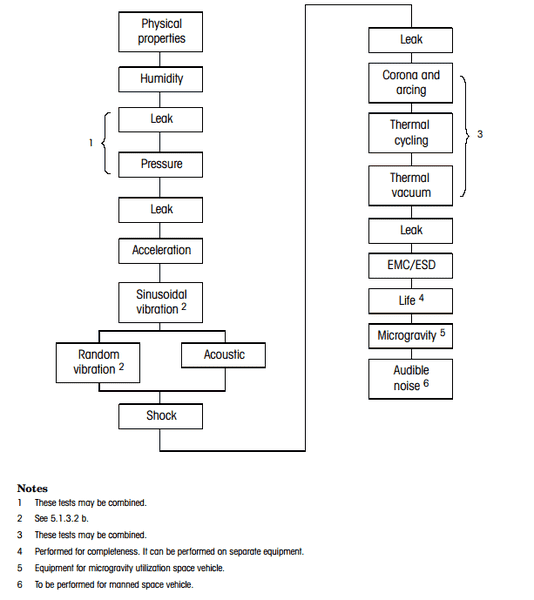

As you very well know, european standards (ecss) exist for space systems but they are generally outlined for launch vehicles. Do specific standards exist for payload fairings? For example a test sequence is outlined for general space vehicles in (ecss e-10-03A) which is :

photos upload

Does a test sequence such as this exist for payload fairings?

Need some guidance on a little issue,

As you very well know, european standards (ecss) exist for space systems but they are generally outlined for launch vehicles. Do specific standards exist for payload fairings? For example a test sequence is outlined for general space vehicles in (ecss e-10-03A) which is :

photos upload

Does a test sequence such as this exist for payload fairings?