Quill

- 2

- 0

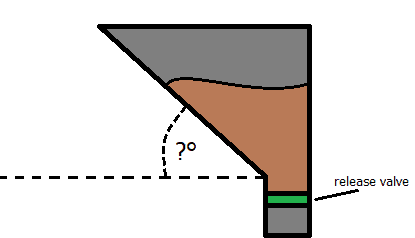

I am an IT student and working on a project, an automated system. It's not for a physics class. I can't say exactly what the system can do. But it uses Arduino to dispense servings of grains on a given schedule. I am more of a programmer than a physicist, I am looking for help on this.

1. Homework Statement

The problem is knowing what the minimum angle the side of the container should incline at, so that the grains will be able to slide down through a tube using gravity. Let's say that an individual grain ranges from 4-7 mm and weighs about 0.028 g. The container will be able to hold up to 5 kg of these grains. One serving will contain around 340 g of grains. The container needs to be completely empty once all the servings of grain has been dispensed, which can take about half or more of a month. That is about 14-15 servings.

What makes this more difficult is that the grains aren't one whole solid object. There will be thousands of grains inside the container. So when the container reaches nearly empty, It'll be difficult knowing how much of an angle (at a minimum) the surface needs to be inclined at to let the few amounts of grain that are left to slide easily without the added weight of the other grains.

Given data:

Grain size = 4-7 mm

Grain weight = 0.028 g

Max weight of grains = 5 kg

Required data:

Minimum inclined angle = X degrees

I am not good at physics. But from researching, this might be a relevant equation:

X = sin^-1 (ax / g)

ax = acceleration on x-axis

g = gravity

I need help with this. I am not even sure if I got the correct equation for my problem.

Also, the reason I am looking for the minimum angle is to help figure out how much space I can work with for other objects that I might put under the container. So I can adjust the inclination based on the minimum for how much space I might need. And also to help adjust the height of the whole system based on whatever needed.

1. Homework Statement

The problem is knowing what the minimum angle the side of the container should incline at, so that the grains will be able to slide down through a tube using gravity. Let's say that an individual grain ranges from 4-7 mm and weighs about 0.028 g. The container will be able to hold up to 5 kg of these grains. One serving will contain around 340 g of grains. The container needs to be completely empty once all the servings of grain has been dispensed, which can take about half or more of a month. That is about 14-15 servings.

What makes this more difficult is that the grains aren't one whole solid object. There will be thousands of grains inside the container. So when the container reaches nearly empty, It'll be difficult knowing how much of an angle (at a minimum) the surface needs to be inclined at to let the few amounts of grain that are left to slide easily without the added weight of the other grains.

Given data:

Grain size = 4-7 mm

Grain weight = 0.028 g

Max weight of grains = 5 kg

Required data:

Minimum inclined angle = X degrees

Homework Equations

I am not good at physics. But from researching, this might be a relevant equation:

X = sin^-1 (ax / g)

ax = acceleration on x-axis

g = gravity

The Attempt at a Solution

I need help with this. I am not even sure if I got the correct equation for my problem.

Also, the reason I am looking for the minimum angle is to help figure out how much space I can work with for other objects that I might put under the container. So I can adjust the inclination based on the minimum for how much space I might need. And also to help adjust the height of the whole system based on whatever needed.