DylanSensor

- 2

- 0

- TL;DR

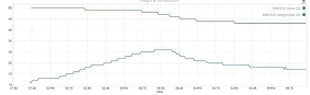

- I am trying to track the thermal expansion of a load cell in rapidly fluctuating temperatures to predict/model the load cell outputs error in regards to temperature.

Hi all,

I am having trouble getting repeatable results from a linear regression formula that simply uses temperature vs load cell output especially with rapidly increasing/decreasing temperatures.

This appears to be a result of the thermal co-efficient of our temperature sensor being almost instant whereas the aluminium load cell appears to take 20-30 minutes before giving stable results. I would like to incorporate the thermal expansion formula with respect to time but having trouble getting my head around it.

PS: Technically a load cell is meant to be a wheatstone bridge which negates the effect of temperature change, this has proven to not be the case on many types of load cells in the application that we are using.

Currently my formula compensates for temperature by adding/subtracting a static value (calculated through a calibration process and using linear regression) per degree of change, however when the temperature changes rapidly, the load cells output does not increase/decrease at the rate at which my formula is compensating for, therefore creating poor results.

Does anyone have any ideas on formulas or methods to help compensate for rapid temperature changes?

Any ideas are appreciated.

Cheers,

Dylan

I am having trouble getting repeatable results from a linear regression formula that simply uses temperature vs load cell output especially with rapidly increasing/decreasing temperatures.

This appears to be a result of the thermal co-efficient of our temperature sensor being almost instant whereas the aluminium load cell appears to take 20-30 minutes before giving stable results. I would like to incorporate the thermal expansion formula with respect to time but having trouble getting my head around it.

PS: Technically a load cell is meant to be a wheatstone bridge which negates the effect of temperature change, this has proven to not be the case on many types of load cells in the application that we are using.

Currently my formula compensates for temperature by adding/subtracting a static value (calculated through a calibration process and using linear regression) per degree of change, however when the temperature changes rapidly, the load cells output does not increase/decrease at the rate at which my formula is compensating for, therefore creating poor results.

Does anyone have any ideas on formulas or methods to help compensate for rapid temperature changes?

Any ideas are appreciated.

Cheers,

Dylan