JP Beaulieu

- 1

- 0

Hi,

I am building a hose system with an automatic liquid dispenser using venturi effect.

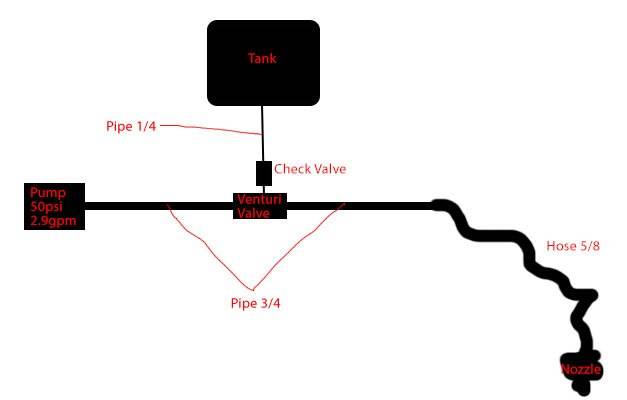

The 12v pump is taking water in a tank via a 3/4 pipe and has a capability of 2.9gpm at 50psi. The main system is built with 3/4 pipes and a 5/8 hose. The siphon pipe is 1/4 and I added a check valve to make sure the water will never go in my liquid tank.

I made an image with the schema of my current prototype.

Everything is working perfectly until I put a nozzle on my hose. When the nozzle is closed, the check valve automatically closes, witch is normal and what I desire.

The problem is, when I open the nozzle, the check valve stay closed. The hole off the nozzle is smaller than the hose to have more pressure. This is probably the cause of the problem.

What am I missing? What can I do to make sure the venturi valve is still working with a nozzle?

Thanks,

J.

I am building a hose system with an automatic liquid dispenser using venturi effect.

The 12v pump is taking water in a tank via a 3/4 pipe and has a capability of 2.9gpm at 50psi. The main system is built with 3/4 pipes and a 5/8 hose. The siphon pipe is 1/4 and I added a check valve to make sure the water will never go in my liquid tank.

I made an image with the schema of my current prototype.

Everything is working perfectly until I put a nozzle on my hose. When the nozzle is closed, the check valve automatically closes, witch is normal and what I desire.

The problem is, when I open the nozzle, the check valve stay closed. The hole off the nozzle is smaller than the hose to have more pressure. This is probably the cause of the problem.

What am I missing? What can I do to make sure the venturi valve is still working with a nozzle?

Thanks,

J.