- #1

VTOL147

- 3

- 1

I am thinking about VTOL jet engine aircrafts like the following example (an ambulance).

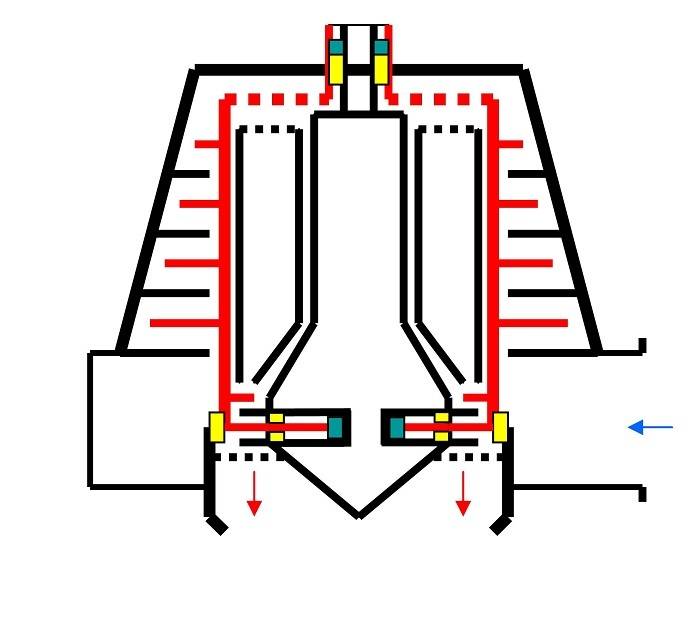

To be able to buid that kind of aircraft VTOL jet engines are needed. At the moment there are no VTOL jet engines available, but I have my own proposal:

I have questions to jet engine experts. Is my design viable? Could the thrust-to-weight be over 50? What about a jet engine with following specs:

- thrust 8000 N (1800 lbf)

- weight 16 kg (35 lb), the thrust-to-weight ratio is 50

- height 300 mm (12")

- diameter 400 mm (16")

More: << Link to personal website deleted by the Mentors >>

To be able to buid that kind of aircraft VTOL jet engines are needed. At the moment there are no VTOL jet engines available, but I have my own proposal:

I have questions to jet engine experts. Is my design viable? Could the thrust-to-weight be over 50? What about a jet engine with following specs:

- thrust 8000 N (1800 lbf)

- weight 16 kg (35 lb), the thrust-to-weight ratio is 50

- height 300 mm (12")

- diameter 400 mm (16")

More: << Link to personal website deleted by the Mentors >>

Last edited by a moderator: