- #1

ENGBIO

- 19

- 1

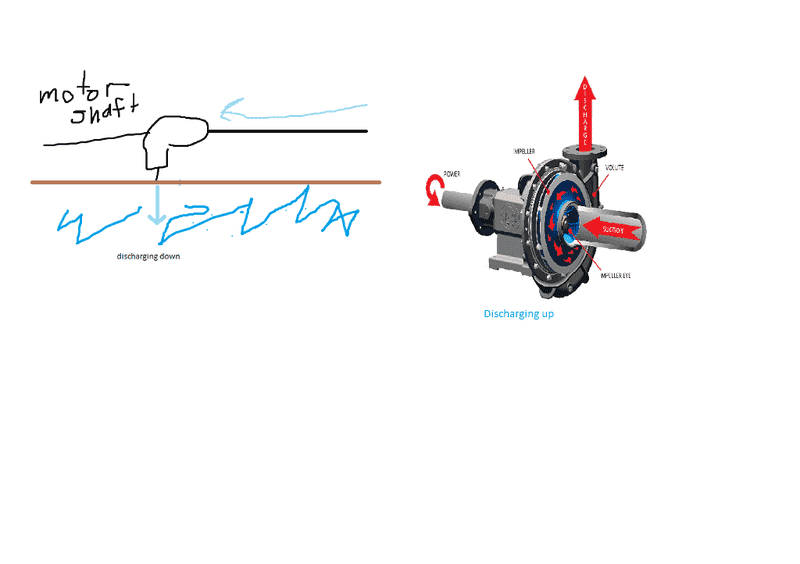

Hello, apologies for the crude drawing. I was wondering if it is possible to have a centrifugal pump that pulls in water and pumps it out down like in the drawn picture? I know usually its to displace water up. I always see centrifugal pumps with discharge oriented up like in the photo. If it can't be used like this what kind of pump can pump it down? This is a pump in a small manned submersible that is pulling water out of a tank and out into the outside to increase positive buoyancy. The pump has a Ns, specific speed, of 61 rpm.