nikola92

- 2

- 0

Hello to all the physics folks. I have a question which I think will be a simple one for you guys.

I bought these mini confetti blowers for our church. They suck confetti, which are mainly small shiny rectangular pieces or some rose shaped paper-like material pieces, and blow them to the air.

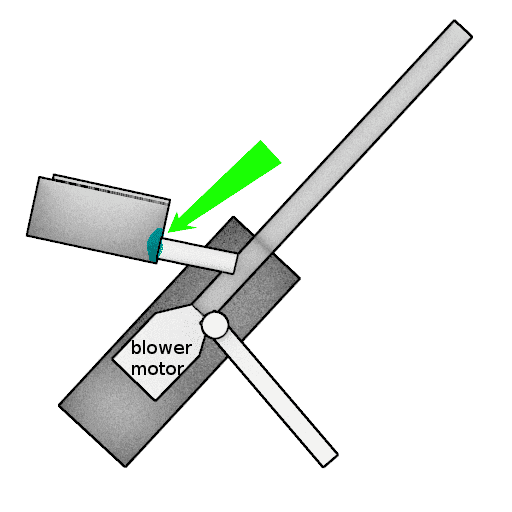

So ours came with a hose setup to suck the confetti:

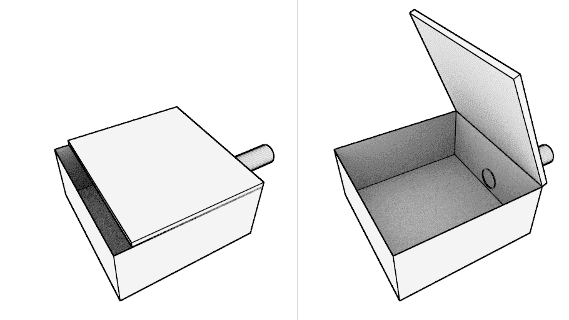

I decided to modify it to suck confetti from inside a box like these ones do:

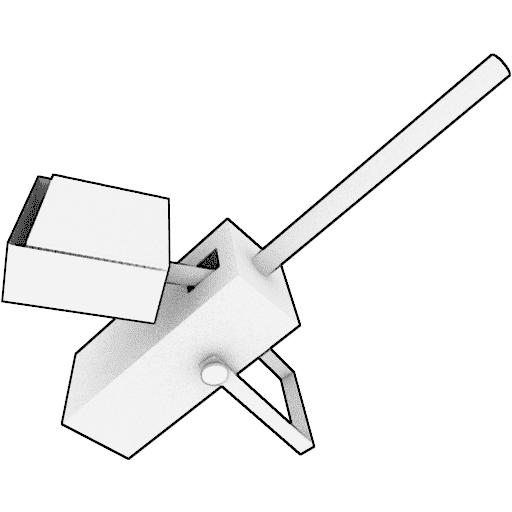

Here's a sketch of how it looks now with the box I made.

What's happening though, the confetti pieces after few seconds form a clog where the box connects with the tube.

If I push that clog with my hand, the confetti is sucked in and flows through the tubes and is blown just fine.

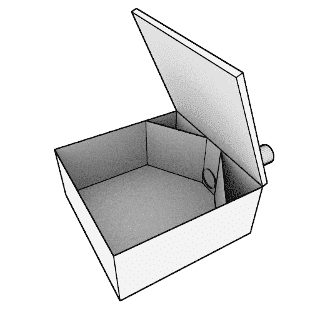

I modified my box from the inside like so, but it didn't change anything.

->

Someone unlike me who actually understands why that is happening, can you explain why clog happens and how would you suggest me to modify my box shape to fix this?Not that the hose setup is bad, it just looks like a modified vacuum cleaner like that and not very pretty to have in ceremonies and we still need a box to put the confetti pieces and the hose into suck the confetti so I thought I could just have the box on the machine itself and make it easier to handle.

I bought these mini confetti blowers for our church. They suck confetti, which are mainly small shiny rectangular pieces or some rose shaped paper-like material pieces, and blow them to the air.

So ours came with a hose setup to suck the confetti:

I decided to modify it to suck confetti from inside a box like these ones do:

Here's a sketch of how it looks now with the box I made.

What's happening though, the confetti pieces after few seconds form a clog where the box connects with the tube.

If I push that clog with my hand, the confetti is sucked in and flows through the tubes and is blown just fine.

I modified my box from the inside like so, but it didn't change anything.

->

Someone unlike me who actually understands why that is happening, can you explain why clog happens and how would you suggest me to modify my box shape to fix this?Not that the hose setup is bad, it just looks like a modified vacuum cleaner like that and not very pretty to have in ceremonies and we still need a box to put the confetti pieces and the hose into suck the confetti so I thought I could just have the box on the machine itself and make it easier to handle.