- #1

Anders Johnsen

- 5

- 0

I'm currently working on my bachelor's thesis in mechanical engineering.

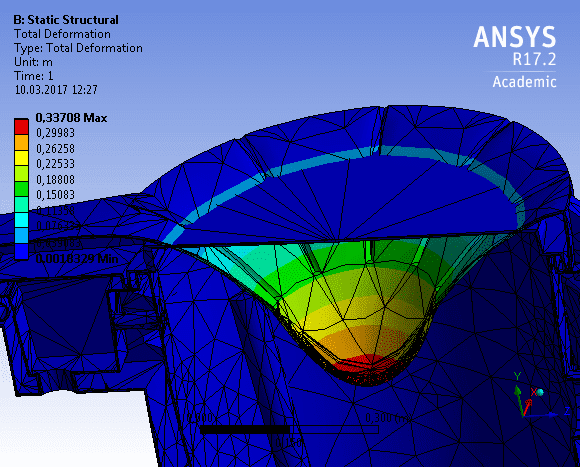

A part of my thesis is conducting a FEM-analysis on a sump for sewage.

I've applied a load on the upper face of the lid for the sump. As a result, the upper layer of the lid has been "pushed through" the lower layer of the lid.

How can this be prevented?

A part of my thesis is conducting a FEM-analysis on a sump for sewage.

I've applied a load on the upper face of the lid for the sump. As a result, the upper layer of the lid has been "pushed through" the lower layer of the lid.

How can this be prevented?