- #1

ANSAN

- 6

- 3

- TL;DR Summary

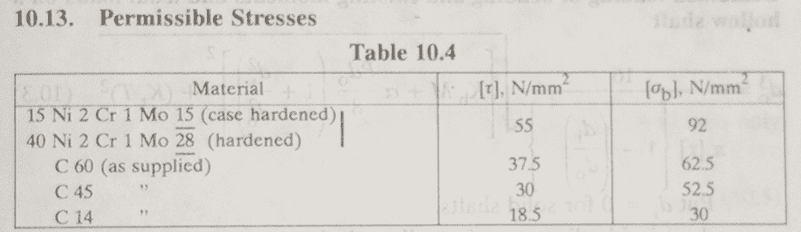

- Need Permissible stress (Shear & Bending) values of various materials that is used for shaft design.

Hi all, i need Permissible stress (Shear & Bending) values of various materials that is used for shaft design, as like below.

Is there any software or excel sheet.

kindly let know.

Is there any software or excel sheet.

kindly let know.

Last edited: