- #1

gfd43tg

Gold Member

- 950

- 50

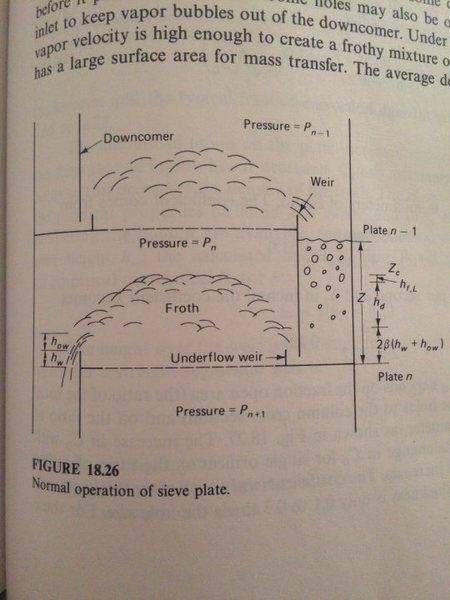

I'm reading McCabe and Thiele's classic "Unit Operations of Chemical Engineering" section about the design of sieve-plate columns. Below is a figure showing a column. I have a few questions and some clarification would be great.

1. Isn't the weir for plate n-1 simply the downcomer for plane n? What is the distinction between a weir and a downcomer?

2. Is vapor from plane n going both through the perforated region (dashed lines), as well as through the underflow weir? Or strictly the perforated region.

3. Even without weeping, wouldn't at least some liquid go through those holes?

4. The pressure drop across a plate is from the friction loss in the holes and the pressure drop due to the hold-up of liquid on the plate. It is expressed as an equivalent head of liquid ##h_t = h_d + h_l## Since it seems to me the liquid is moving from the downcomer towards the weir, there is friction loss whether or not you have holes. Isn't that friction loss from the vapor coming up the holes? What is the pressure drop from hold-up of liquid on the plate? Is that like an accumulation of liquid on the plate until it reaches the height of the weir over the plate? You can see from the figure that the weir is slightly taller than the plate. I guess I don't understand hydraulically what liquid-hold up pressure drop is.

5. When it speaks of a pressure on a plate, shouldn't that depend on where on the plate you are talking? There should be a vertical pressure difference that allows vapor to flow from one plate through the holes into the next place, as well as horizontal pressure difference that allows the liquid to flow from the downcomer over to the weir.

6. In the operation limits for sieve trays section, it states

1. Isn't the weir for plate n-1 simply the downcomer for plane n? What is the distinction between a weir and a downcomer?

2. Is vapor from plane n going both through the perforated region (dashed lines), as well as through the underflow weir? Or strictly the perforated region.

3. Even without weeping, wouldn't at least some liquid go through those holes?

4. The pressure drop across a plate is from the friction loss in the holes and the pressure drop due to the hold-up of liquid on the plate. It is expressed as an equivalent head of liquid ##h_t = h_d + h_l## Since it seems to me the liquid is moving from the downcomer towards the weir, there is friction loss whether or not you have holes. Isn't that friction loss from the vapor coming up the holes? What is the pressure drop from hold-up of liquid on the plate? Is that like an accumulation of liquid on the plate until it reaches the height of the weir over the plate? You can see from the figure that the weir is slightly taller than the plate. I guess I don't understand hydraulically what liquid-hold up pressure drop is.

5. When it speaks of a pressure on a plate, shouldn't that depend on where on the plate you are talking? There should be a vertical pressure difference that allows vapor to flow from one plate through the holes into the next place, as well as horizontal pressure difference that allows the liquid to flow from the downcomer over to the weir.

6. In the operation limits for sieve trays section, it states

What is liquid head? I have always had a very muddied understanding of the term "head" used in hydraulics. There are velocity heads, pressure heads, liquid heads, every type of head conceivable and it confuses me.At low vapor velocities, the pressure drop is not great enough to prevent liquid from flowing down through some of the holes. This condition is called weeping and is more likely to occur if there is a slight gradient in the liquid head across the plate.