- #1

kingneptune11

- 10

- 0

Hello all,

I am a mechanical engineer, graduated just last year. Although I am not working with fluid mechanics right now, I was browsing through my fluids book from school and saw the section on pipe networks. As I was reading, I developed this question which I could not find an answer to in the book.

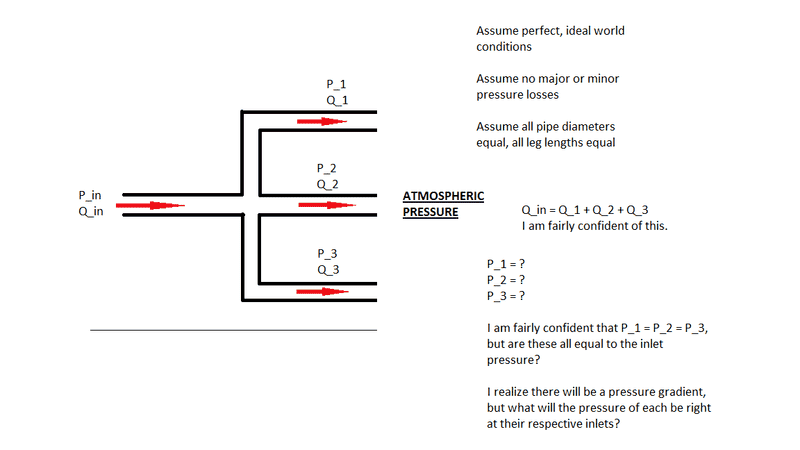

Please see the attached image below.

Please note, for my question, let's assume perfect world conditions (all pipes same diameter, all leg lengths are equal, no frictional major/minor losses, etc...)

In the image, you can see we have one inlet, with pressure P_in and flow rate Q_in. My question is about what happens when you branch out into the three branches. I realize that flow rate will split evenly (in a perfect world), but what happens to the pressures?

Keep in mind, the three branches are open to atmosphere. Due to this, I realize there will be a pressure gradient, with the exit pressure reaching 0 (atmosphere). But let's say I am asking about the pressures at each of the branches inlets. Does P_in = P_1 = P_2 = P_3 in an ideal world?

Basically, I have a decent understanding of how flow rates will split when the flow hits the three branches, but how does the pressure of each of the three branches relate to the pressure of the main inlet (P_in)? My hypothesis is that P_in = P_1 = P_2 = P_3, assuming we are talking about the branches inlets (by inlets, I mean where the branches connect to the main pipe).

Thank you for your time and help. Please let me know if I need to further clarify my question. Also, I apologize in advance if this is in the wrong sub-forum. Mods, please move if necessary. Thank you.

I am a mechanical engineer, graduated just last year. Although I am not working with fluid mechanics right now, I was browsing through my fluids book from school and saw the section on pipe networks. As I was reading, I developed this question which I could not find an answer to in the book.

Please see the attached image below.

Please note, for my question, let's assume perfect world conditions (all pipes same diameter, all leg lengths are equal, no frictional major/minor losses, etc...)

In the image, you can see we have one inlet, with pressure P_in and flow rate Q_in. My question is about what happens when you branch out into the three branches. I realize that flow rate will split evenly (in a perfect world), but what happens to the pressures?

Keep in mind, the three branches are open to atmosphere. Due to this, I realize there will be a pressure gradient, with the exit pressure reaching 0 (atmosphere). But let's say I am asking about the pressures at each of the branches inlets. Does P_in = P_1 = P_2 = P_3 in an ideal world?

Basically, I have a decent understanding of how flow rates will split when the flow hits the three branches, but how does the pressure of each of the three branches relate to the pressure of the main inlet (P_in)? My hypothesis is that P_in = P_1 = P_2 = P_3, assuming we are talking about the branches inlets (by inlets, I mean where the branches connect to the main pipe).

Thank you for your time and help. Please let me know if I need to further clarify my question. Also, I apologize in advance if this is in the wrong sub-forum. Mods, please move if necessary. Thank you.