FEAnalyst

- 348

- 149

- TL;DR

- How to calculate the angle of twist from in-plane displacements?

Hi,

solid elements used in FEA don't have rotational DOFs so normally it's not possible to read the angle of twist from simulation involving torsion. Some programs allow the transformation of results to cylindrical coordinate system but it's not always the case. From what I've heard, it's possible to use in-plane displacement values to determine the angle of twist. However, I'm not sure how to actually do it. Here's an example of an elliptical bar subjected to torsion:

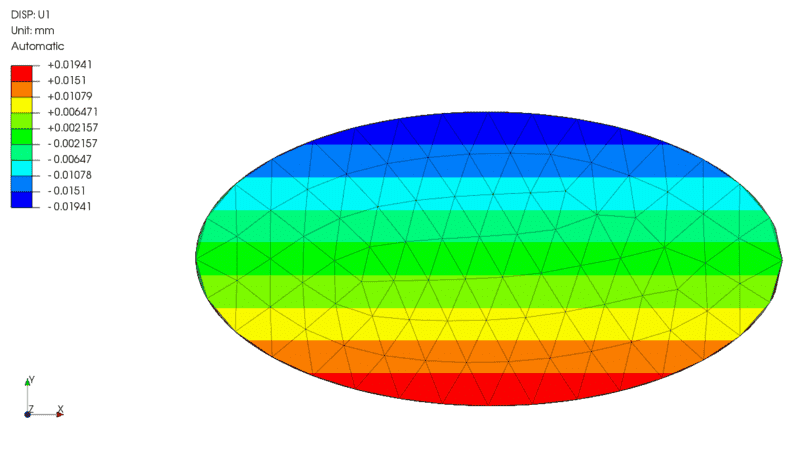

- X displacements:

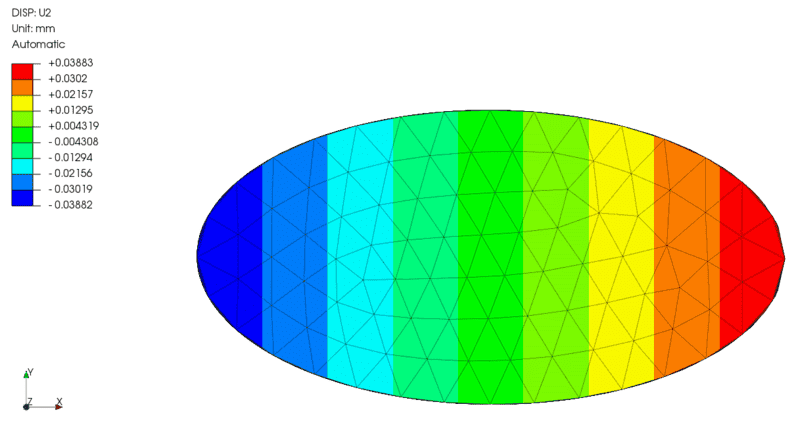

- Y displacements:

How can I calculate the angle of twist from these displacement values? Or maybe it's not enough and nodal coordinates are needed as well?

Thanks in advance for your help.

solid elements used in FEA don't have rotational DOFs so normally it's not possible to read the angle of twist from simulation involving torsion. Some programs allow the transformation of results to cylindrical coordinate system but it's not always the case. From what I've heard, it's possible to use in-plane displacement values to determine the angle of twist. However, I'm not sure how to actually do it. Here's an example of an elliptical bar subjected to torsion:

- X displacements:

- Y displacements:

How can I calculate the angle of twist from these displacement values? Or maybe it's not enough and nodal coordinates are needed as well?

Thanks in advance for your help.