- #1

Nikhil N

- 81

- 2

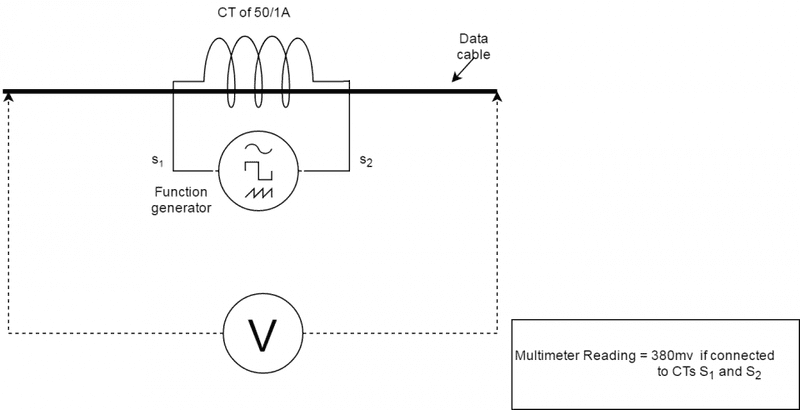

I have to couple noise into data cable(cat5) in common mode. I have done this with a CT of 50A/1A, ferrite core. What I have done is, I connected the S1 and S2 of CT to probe of my signal generator and inserted the cable through the whole of CT(ring type). I got maximum of 380mV in the cable ends when only the signal from signal generator fed no data is transferring. But I have to couple atleast 1V to the cable. I want to know how can increase this, whether should I increase the turns on the ferrite core or any other method ? If I should increase the no of turns, how to calculate the no of turns and the wire specifications? (I used 200KHz, 10Vpp AC signal)