DefinitelyAnEnjinear

- 10

- 6

- TL;DR Summary

- Discussing the practical and moral limitation of mounting the driving pin on the driven wheel in a geneva mechanism.

(note: I never studied engineering, but I think I have a good math (and slight physics) background. I'm mentioning this not so you'll go easy on me - if I don't understand something, I'm sure I'll figure it out or find someone to help me decode what you're saying. I'm mentioning this in the hopes you'll forgive mistakes or failures to communicate that may seem obvious to you.)

A while ago, I posted about a geneva mechanism I was trying to design.

My goal was to have the driving pin mounted on the driven wheel, pushing against something that doesn't move (either a dial pushing against some pins as in my latest attempt, or a gear with a single tooth pushing against a gear) to cause the intermittent motion.

An earlier attempt I posted:

as someone pointed out, this one lacked a locking mechanism.

I've designed one with a locking mechanism, which overcame a previous problem (dragging) but not my jamming problem - when the dial engages the pins/the tooth egnages the gear and the driven wheel is supposed to rotate, it gets stuck.

As can be seen in the gif I posted, if I cheat and rotate the gear mounted on the driven wheel myself (rather than driving it through a gear in the center), it works - not just in the version without a lock, but in the one with a lock as well.

I don't have a video of a version with a locking mechanism to share (I've allowed myself to lose track of the 3D printed pieces of some of the attempts because I planned on making more attempts before asking for help again, but my attempts to get my 3D printer to print properly have all failed so far)

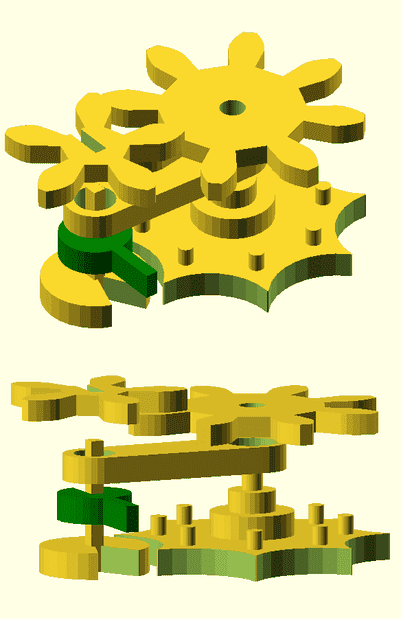

my latest design (the one that I hadn't managed to print - a previous one with a gear instead of pins and a 1-toothed gear instead of a dial that I did print also didn't work)

A while ago, I posted about a geneva mechanism I was trying to design.

My goal was to have the driving pin mounted on the driven wheel, pushing against something that doesn't move (either a dial pushing against some pins as in my latest attempt, or a gear with a single tooth pushing against a gear) to cause the intermittent motion.

An earlier attempt I posted:

as someone pointed out, this one lacked a locking mechanism.

I've designed one with a locking mechanism, which overcame a previous problem (dragging) but not my jamming problem - when the dial engages the pins/the tooth egnages the gear and the driven wheel is supposed to rotate, it gets stuck.

As can be seen in the gif I posted, if I cheat and rotate the gear mounted on the driven wheel myself (rather than driving it through a gear in the center), it works - not just in the version without a lock, but in the one with a lock as well.

I don't have a video of a version with a locking mechanism to share (I've allowed myself to lose track of the 3D printed pieces of some of the attempts because I planned on making more attempts before asking for help again, but my attempts to get my 3D printer to print properly have all failed so far)

my latest design (the one that I hadn't managed to print - a previous one with a gear instead of pins and a 1-toothed gear instead of a dial that I did print also didn't work)