- #1

hughfrancis89

- 2

- 0

Hi there! I have recently taken on an engineering job and have been tasked with designing a simple beam support for an exhaust pipe.

Because I'm still studying and I want to make sure I do this properly, I have decided to consult Physics Forums, as reading others posts have helped me so much in the past.

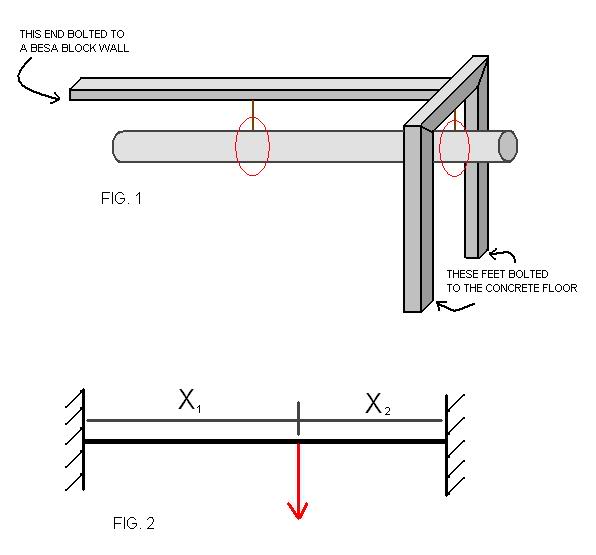

I have attached a picture of the design to this post. Basically I've just got to make sure there is a significant safety factor against yielding with the setup.

I don't have any numbers to work with currently, I'm just getting the theory down pat first.

I assume I need to find the yield stress of the material, and compare that to the bending stress currently caused by the load from the pipe. Also, how would I calculate the load caused by the pipe on each support? Would it just be the weight of the pipe divided by two (due to the two supports) or would it be more complicated than that, because the supports arent evenly spaced?

Also I assume to model the top beam I would just use a fixed end beam as in FIG 2.

Thanks for the advice, apologies for the simple question!

Hugh

Because I'm still studying and I want to make sure I do this properly, I have decided to consult Physics Forums, as reading others posts have helped me so much in the past.

I have attached a picture of the design to this post. Basically I've just got to make sure there is a significant safety factor against yielding with the setup.

I don't have any numbers to work with currently, I'm just getting the theory down pat first.

I assume I need to find the yield stress of the material, and compare that to the bending stress currently caused by the load from the pipe. Also, how would I calculate the load caused by the pipe on each support? Would it just be the weight of the pipe divided by two (due to the two supports) or would it be more complicated than that, because the supports arent evenly spaced?

Also I assume to model the top beam I would just use a fixed end beam as in FIG 2.

Thanks for the advice, apologies for the simple question!

Hugh