DefinitelyAnEnjinear

- 10

- 6

- TL;DR

- Designing a spiral with a 45 degree angle relative to the movement of a disk orbiting around a point

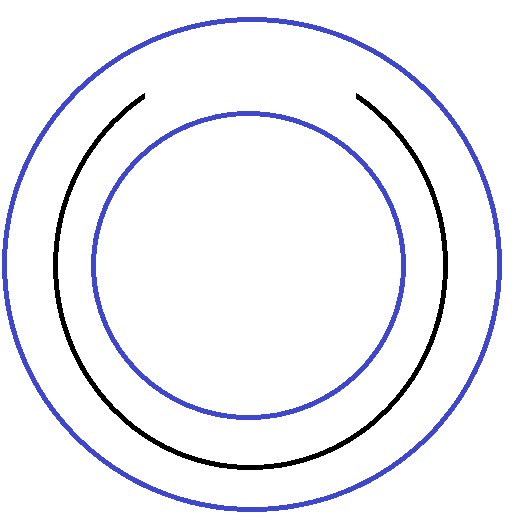

I have a disk traveling on the inner blue track (let's say the blue part is the center of the disk).

I want to push the disk outside (as the disk is traveling in a circle) to the outer track.

The black part is the wall separating the tracks

To that end, I've made some calculations, but I have some concerns regarding my results, and am wondering if there's a better way to go about it.

I have a decent math background, but no engineering background at all.

I started out by noting the direction of movement for the disk, say it's moving counter-clockwise. If c is a point on the inner circle (for simplicity: unit circle), then the movement direction is determined as follows:

Also, some relevant trigonometric identities:

where Δθ is the angle between u and v.

Let's say I want a 45 degree angle between my spiral and the movement direction of the disk (my very limited physics knowledge tells me a steeper angle would require more force to be applied because more of the "equal and opposite reaction" thing would be in the direction that's against the disk movement. Obviously a smaller angle would mean it takes longer to get the disk as far as I need it to go).

The sine and cosine of 45 degrees go without saying, yielding:

And after doing some mathTM

So now we have v, which... I'm not sure how to put this into words in a technically accurate way, so let's say it's the direction of the tangent to the spiral. Meaning its slope is that of the derivative. Meaning:

is the derivative of the function describing my spiral, with α being the angle between the x-axis and the vector pointing to some point on the circle.

This is the part where I start to get worried and confused, because (1) I potentially have a division by 0 here, and (2) the point is to move the disk during rotation and I'm not sure if my reasoning still holds at this point.

With a little help from wikipedia I got to:

Being my derivative.

So if, say, I wanted to start the transition when we're at 45 degrees... I start off on a singularity.

So, did I get anything wrong? Is there a better approach to solving this problem?

I want to push the disk outside (as the disk is traveling in a circle) to the outer track.

The black part is the wall separating the tracks

To that end, I've made some calculations, but I have some concerns regarding my results, and am wondering if there's a better way to go about it.

I have a decent math background, but no engineering background at all.

I started out by noting the direction of movement for the disk, say it's moving counter-clockwise. If c is a point on the inner circle (for simplicity: unit circle), then the movement direction is determined as follows:

Also, some relevant trigonometric identities:

where Δθ is the angle between u and v.

Let's say I want a 45 degree angle between my spiral and the movement direction of the disk (my very limited physics knowledge tells me a steeper angle would require more force to be applied because more of the "equal and opposite reaction" thing would be in the direction that's against the disk movement. Obviously a smaller angle would mean it takes longer to get the disk as far as I need it to go).

The sine and cosine of 45 degrees go without saying, yielding:

And after doing some mathTM

So now we have v, which... I'm not sure how to put this into words in a technically accurate way, so let's say it's the direction of the tangent to the spiral. Meaning its slope is that of the derivative. Meaning:

is the derivative of the function describing my spiral, with α being the angle between the x-axis and the vector pointing to some point on the circle.

This is the part where I start to get worried and confused, because (1) I potentially have a division by 0 here, and (2) the point is to move the disk during rotation and I'm not sure if my reasoning still holds at this point.

With a little help from wikipedia I got to:

Being my derivative.

So if, say, I wanted to start the transition when we're at 45 degrees... I start off on a singularity.

So, did I get anything wrong? Is there a better approach to solving this problem?