caslor

- 4

- 0

Hi

i have 3 wire ropes that holding a weight and i want to have the same tension in all of them.

there are some devices all ready in the market bat costs a lot of money.. 500 dollars/euro and more

like this onei was thinking to build my own device..

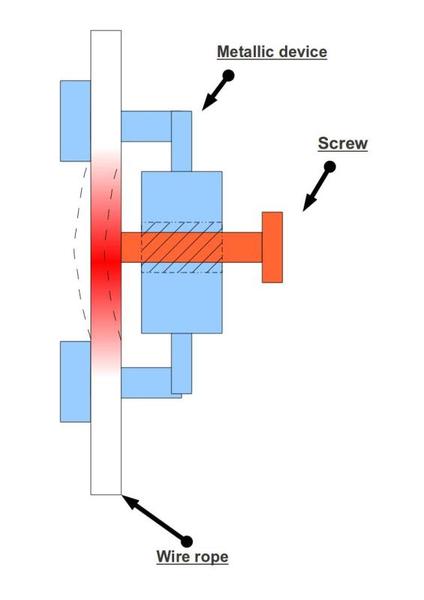

like this one :

screw with my Torque wrench until a specific distance in wire rope curve...

after that i move the device to the other wire rope and torgue it until i have the same distance/curve

see how much torque needed to have the same curve and adjust the tension of the wire rope...

what do you think?

that will work?

i have 3 wire ropes that holding a weight and i want to have the same tension in all of them.

there are some devices all ready in the market bat costs a lot of money.. 500 dollars/euro and more

like this onei was thinking to build my own device..

like this one :

screw with my Torque wrench until a specific distance in wire rope curve...

after that i move the device to the other wire rope and torgue it until i have the same distance/curve

see how much torque needed to have the same curve and adjust the tension of the wire rope...

what do you think?

that will work?

Homework Statement

Homework Equations

The Attempt at a Solution

Last edited by a moderator: