- #1

Sorade

- 53

- 1

Hi all,

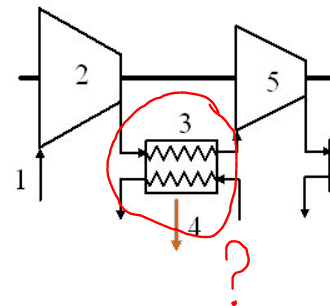

I am looking at a air compressor train design which looks like this:

I know how to work the compressor work needed for a two stage compressor, and hence how much work I can save using 2 instead of 1 stage.

The question I have is: How much energy does it require to operate an intercooler (in red on figure) ?

How do the savings in work compare to that. I was asked the question today while giving a talk and couldn't answer it. I am not an engineer.

Thank you for your help

I am looking at a air compressor train design which looks like this:

I know how to work the compressor work needed for a two stage compressor, and hence how much work I can save using 2 instead of 1 stage.

The question I have is: How much energy does it require to operate an intercooler (in red on figure) ?

How do the savings in work compare to that. I was asked the question today while giving a talk and couldn't answer it. I am not an engineer.

Thank you for your help