KatrineRav

- 13

- 1

Hi!

I'm working in a new area and I'm looking for inputs/suggestions for relevant factors to look into and possible ressource where I can read about this :)

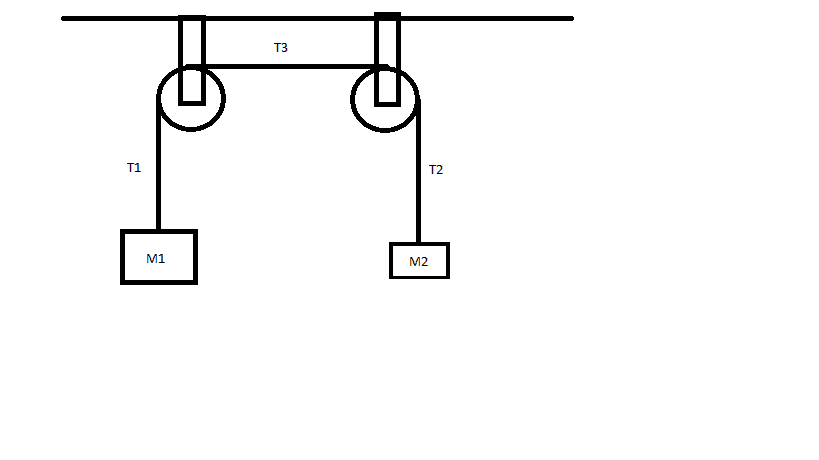

I did some tests in a pulley similar to the one below.

I had a fixed weight at M2. I started with M1=M2 but added weights to M1 until the weights started moving (M1 down and M2 up). I believe my measurements can be used to say something about static friction in the system.

I am now trying to explain why M1 has to be quite a bit heavier than M2 for the system to start moving.

I know the following:

- there is friction between rope and pulley. The static friction keeps the rope from slipping over the surface and makes the pulley rotate when the rope is pulled. I don't think this is relevant since it does not oppose the movement of M1 and M2.

- there is friction between the pulley and the axle. I believe this results in a torque opposing the movement. I believe this is the factor I'm interested in.

PROBLEM STATEMENT

Not totally sure! Something like "Quantify the forces opposing movement in the pulley system and explain why M1 has to be (quite a bit) larger than M2 before the system starts moving)

DATA

This is my dataset. Masses are measured in kg.

m2 m1

23,9 31,8

34 42,7

43,4 51,32. + 3. Relevant equations + attempt at a solution

I'm not totally sure.

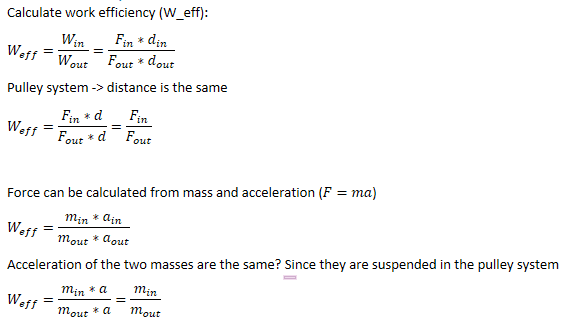

WORK EFFICIENCY

I could say that the loss might be due to friction in

FRICTION

I'm not sure whether I should look into static friction on a surface or belt friction

Final remarks

I've been researching the problem for a few hours, but I simply can't figure out where to start! I hope you can point me in the right direction! :)

I'm working in a new area and I'm looking for inputs/suggestions for relevant factors to look into and possible ressource where I can read about this :)

I did some tests in a pulley similar to the one below.

I had a fixed weight at M2. I started with M1=M2 but added weights to M1 until the weights started moving (M1 down and M2 up). I believe my measurements can be used to say something about static friction in the system.

I am now trying to explain why M1 has to be quite a bit heavier than M2 for the system to start moving.

I know the following:

- there is friction between rope and pulley. The static friction keeps the rope from slipping over the surface and makes the pulley rotate when the rope is pulled. I don't think this is relevant since it does not oppose the movement of M1 and M2.

- there is friction between the pulley and the axle. I believe this results in a torque opposing the movement. I believe this is the factor I'm interested in.

Homework Statement

PROBLEM STATEMENT

Not totally sure! Something like "Quantify the forces opposing movement in the pulley system and explain why M1 has to be (quite a bit) larger than M2 before the system starts moving)

DATA

This is my dataset. Masses are measured in kg.

m2 m1

23,9 31,8

34 42,7

43,4 51,32. + 3. Relevant equations + attempt at a solution

I'm not totally sure.

WORK EFFICIENCY

I could say that the loss might be due to friction in

FRICTION

I'm not sure whether I should look into static friction on a surface or belt friction

Final remarks

I've been researching the problem for a few hours, but I simply can't figure out where to start! I hope you can point me in the right direction! :)