- #1

theicecreamda

- 1

- 0

I'm attempting to repair a glass aquarium.

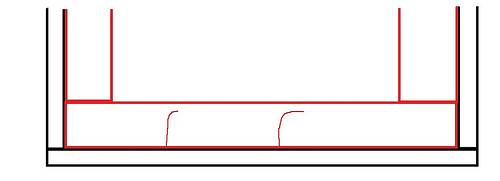

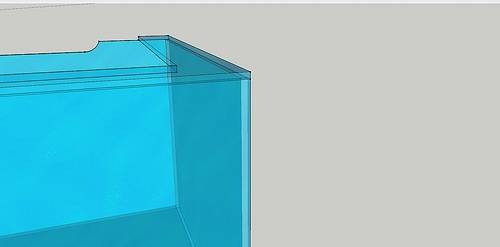

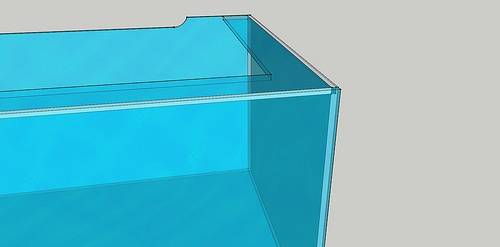

Here is a drawing I made when I ordered it originally,

the top brace has developed 2 small cracks.

So I'd like to empty the tank, then remove the old brace, and replace it.

But I'm trying to figure out what dimensions I need the new piece to be.

Can it be cut to match the outer dimensions of the vertical sides, and sit on top?

Or does it need to sit inside, flush with the top edge of the vertical sides?

The first style would be a lot easier to do in this situation, but as it sits, the brace is in the second spot.

Why can't I find anything about the differences between shear and tensile strength of this joint? Does it even matter? I can see that the vertical edges are experiencing both of these loads.

edit: I found this

http://www.mgchemicals.com/products/108.html

Cured Properties - MECHANICAL

Hardness 30 (Shore A)

Tensile Strength 28 kg/cm2 (400 psi)

Elongation 450%

Tear Strength 8 kg/cm (45 lb/in)

Peel Strength 7 kg/cm (40 lb/in)

Here is a drawing I made when I ordered it originally,

the top brace has developed 2 small cracks.

So I'd like to empty the tank, then remove the old brace, and replace it.

But I'm trying to figure out what dimensions I need the new piece to be.

Can it be cut to match the outer dimensions of the vertical sides, and sit on top?

Or does it need to sit inside, flush with the top edge of the vertical sides?

The first style would be a lot easier to do in this situation, but as it sits, the brace is in the second spot.

Why can't I find anything about the differences between shear and tensile strength of this joint? Does it even matter? I can see that the vertical edges are experiencing both of these loads.

edit: I found this

http://www.mgchemicals.com/products/108.html

Cured Properties - MECHANICAL

Hardness 30 (Shore A)

Tensile Strength 28 kg/cm2 (400 psi)

Elongation 450%

Tear Strength 8 kg/cm (45 lb/in)

Peel Strength 7 kg/cm (40 lb/in)

Last edited by a moderator: