spudsquad

- 3

- 0

i am a sophomore and just started my first co-op and the boss left me with this problem to solve that seems to be slightly beyond my knowledge so far. The whole problem is too long but here is the part i am stuck on.

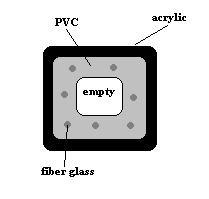

I have a sample material that is being made and fed out of a machine, so it is infinitely long. The sample looks like this:

it comes out at a temperature of 450F, and into a tank that is 65 degrees F.

What i need to find is how long before the fiberglass is 300F.

I have looked up specific heats, thermal conductivities, and all the dimensions.

I am having trouble even just finding the when the PVC will be 300F, i have read for hours online for ways to do this and can't seem to find a similar problem. This is my first post on the forum and would really appreciate any tips on the method to solve this, or if i even have enough information.

thanks.

attempts:

- i tried Newtons law of cooling and the conduction equation. the main problem i keep having is that all the formulas are dependent on difference in temperature and the temperature for both the acrylic and pvc are constantly changing.

I have a sample material that is being made and fed out of a machine, so it is infinitely long. The sample looks like this:

it comes out at a temperature of 450F, and into a tank that is 65 degrees F.

What i need to find is how long before the fiberglass is 300F.

I have looked up specific heats, thermal conductivities, and all the dimensions.

I am having trouble even just finding the when the PVC will be 300F, i have read for hours online for ways to do this and can't seem to find a similar problem. This is my first post on the forum and would really appreciate any tips on the method to solve this, or if i even have enough information.

thanks.

attempts:

- i tried Newtons law of cooling and the conduction equation. the main problem i keep having is that all the formulas are dependent on difference in temperature and the temperature for both the acrylic and pvc are constantly changing.