Gevorg

- 7

- 0

I am currently performing failure analysis on an A356 Aluminum alloy wheel subjected to rotational loading, with a maximum load of 650 kgf and a torque of 4600 Nm. Cracks formed in the wheel after 1.3*10^6 rotations.

My job is to perform a stress analysis to determine the regions of maximum stress concentration under such loading conditions. I figured it is first necessary to draw a free body diagram of the entire wheel and then apply the method of sections, in which I would make cuts along specific regions of the wheel and determine the forces acting on them.

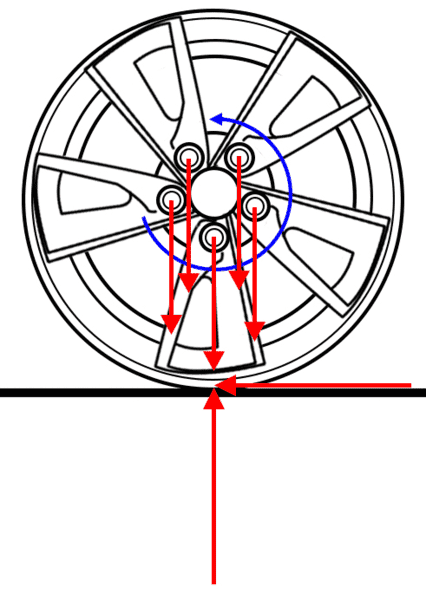

Below I've drawn a free body diagram of the wheel. The sum of the forces acting on the 5 holes should equal 650 kgf. The up pointing arrow is equal in magnitude to their sum. The applied torque, shown in blue, should be equal in magnitude to the torque generated by the left pointing force of friction in order for the wheel to rotate at a constant angular velocity.

I still feel that something is missing and can't quite put my finger on it. Could someone provide some insight?

My job is to perform a stress analysis to determine the regions of maximum stress concentration under such loading conditions. I figured it is first necessary to draw a free body diagram of the entire wheel and then apply the method of sections, in which I would make cuts along specific regions of the wheel and determine the forces acting on them.

Below I've drawn a free body diagram of the wheel. The sum of the forces acting on the 5 holes should equal 650 kgf. The up pointing arrow is equal in magnitude to their sum. The applied torque, shown in blue, should be equal in magnitude to the torque generated by the left pointing force of friction in order for the wheel to rotate at a constant angular velocity.

I still feel that something is missing and can't quite put my finger on it. Could someone provide some insight?