Pejeu

- 27

- 1

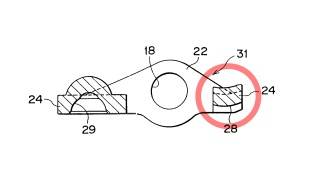

of a surface of a part that rotates about a pivot point such that there is rolling instead of sliding contact at the interface between that part, along that curved surface, and another part, with a flat surface against which the first one pushes as it rotates about its pivot.

I want to design a roller rocker/finger follower engagement area with the stem of poppet valve.

How can one compute that or where can one read on how to do it?

I want to design a roller rocker/finger follower engagement area with the stem of poppet valve.

How can one compute that or where can one read on how to do it?