- #1

AZFIREBALL

- 228

- 103

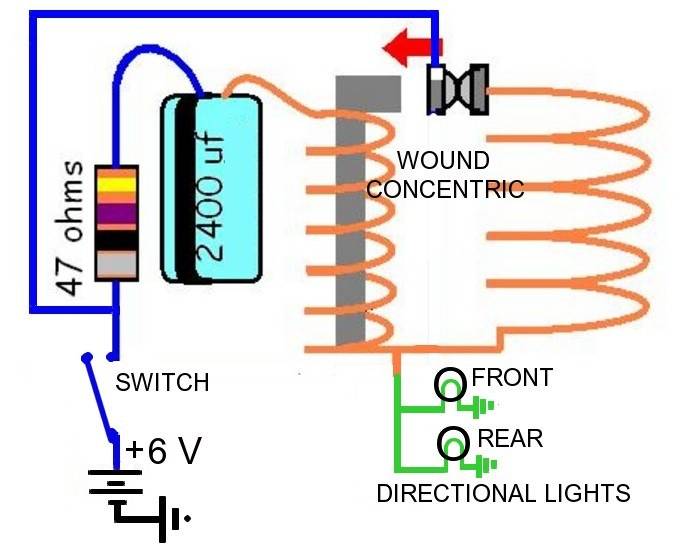

This is a diagram of an old 1970's directional flasher switch. Can anyone walk me thru the details of its operation?

https://drive.google.com/open?id=1OI6bL3PXfDx8lmg2eiWDCVHg9rgm0gYl

Thanks.

https://drive.google.com/open?id=1OI6bL3PXfDx8lmg2eiWDCVHg9rgm0gYl

Thanks.

Attachments

Last edited: