sach2606

- 2

- 0

hi

Wondering if someone could help.

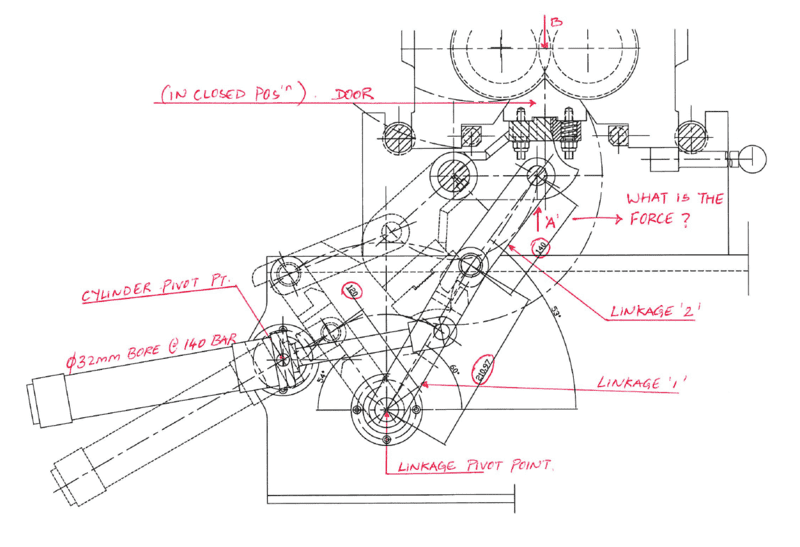

I need to know how to work out the the force at point 'A' ( see sketch attached).

Its a door opening and closing mechanism and it consists of a hydraulic cylinder 32mm dia bore operating at 140 bar. The door is opened and closed via couple of linkages as the cylinder opens and retracts.

I presume there will be some force losses due to the linkages at point 'A'. I am struggling to work out what will be the force at 'A' when the door is in closed position to ensure we don't put enough force at point 'B' for it to open.

Your help will be much appreciated.

Wondering if someone could help.

I need to know how to work out the the force at point 'A' ( see sketch attached).

Its a door opening and closing mechanism and it consists of a hydraulic cylinder 32mm dia bore operating at 140 bar. The door is opened and closed via couple of linkages as the cylinder opens and retracts.

I presume there will be some force losses due to the linkages at point 'A'. I am struggling to work out what will be the force at 'A' when the door is in closed position to ensure we don't put enough force at point 'B' for it to open.

Your help will be much appreciated.