fuhandaigou

- 5

- 0

Powerful rotary engine?

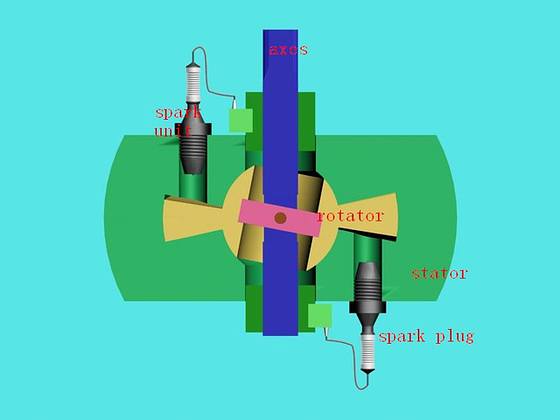

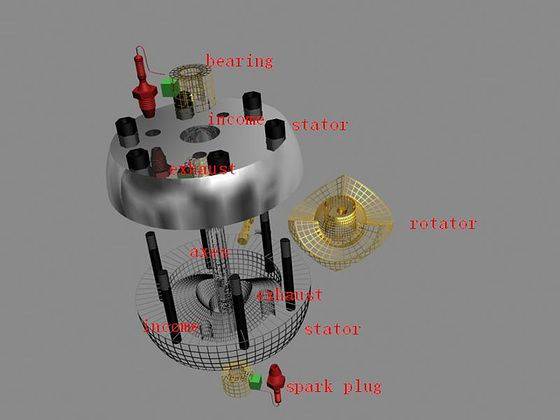

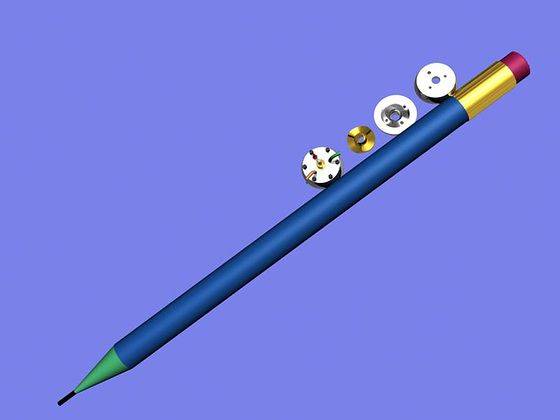

This is a powerful rotary internal combustion engine. When rotor round one time, engine work six times.My mechanical design aim was to create a power for UAV,MAV, robotics, mini-generators; engine size is very small, can be forged or EDM etching method of mass production. Because the rotor around its axis, uniform rotation, so it can reach a very high speed, high power.

Currently, power machinery, achieve practical machine are wankel engine, RCV engine, and there is a traditional four-stroke internal combustion engines, two-stroke internal combustion engine, and so on. They have their advantages, but also have their shortcomings. Especially the mechanical size less than 1 cm, the disadvantages of exposure of particularly, RCV engine, the traditional four-stroke internal combustion engine and two-stroke engine with considerable difficulty processing, especially tiny part of the process is more difficult, the production cost is very high, the work reliability was really bad. Wankel engine’s parts relatively few, small size relative high reliability, but cutting machining is difficult, difficult to implement low-cost lot size

Production.while my engine rotor and stator's face is an irregular surface, machining difficult too, but the face is smooth, in small size, available material in plastic processing technology for low-cost of production and the use of plastic processing methods are forging, EDM etching, forging will not only enable low-cost production quantities, but also can improve the mechanical parts of the structure, part of the strength and surface finish. Adopting EDM etching, can improve parts of sealing and wear resistance, the specific method is: etch out a lot of fine grooves on the moving parts which need sealing, forming the labyrinth, with labyrinth seals, improve sealing performance. and on the sliding contact surface, etching a lot small pits, lubricants, as far as possible remain in these areas, to improve the machinery lubrication performance.

study the 3D images that I upload on to forums, that structure, you should understand that was not possible work, because the rotor projecting too sharp, not only the room’s sealing cannot be guaranteed, and the normal rotation of the rotor cannot be guaranteed. There are a lot of problems you can see, after all, is a previous primary design! If you are interested in,Your views? email sky-hawk@126.com

This is a powerful rotary internal combustion engine. When rotor round one time, engine work six times.My mechanical design aim was to create a power for UAV,MAV, robotics, mini-generators; engine size is very small, can be forged or EDM etching method of mass production. Because the rotor around its axis, uniform rotation, so it can reach a very high speed, high power.

Currently, power machinery, achieve practical machine are wankel engine, RCV engine, and there is a traditional four-stroke internal combustion engines, two-stroke internal combustion engine, and so on. They have their advantages, but also have their shortcomings. Especially the mechanical size less than 1 cm, the disadvantages of exposure of particularly, RCV engine, the traditional four-stroke internal combustion engine and two-stroke engine with considerable difficulty processing, especially tiny part of the process is more difficult, the production cost is very high, the work reliability was really bad. Wankel engine’s parts relatively few, small size relative high reliability, but cutting machining is difficult, difficult to implement low-cost lot size

Production.while my engine rotor and stator's face is an irregular surface, machining difficult too, but the face is smooth, in small size, available material in plastic processing technology for low-cost of production and the use of plastic processing methods are forging, EDM etching, forging will not only enable low-cost production quantities, but also can improve the mechanical parts of the structure, part of the strength and surface finish. Adopting EDM etching, can improve parts of sealing and wear resistance, the specific method is: etch out a lot of fine grooves on the moving parts which need sealing, forming the labyrinth, with labyrinth seals, improve sealing performance. and on the sliding contact surface, etching a lot small pits, lubricants, as far as possible remain in these areas, to improve the machinery lubrication performance.

study the 3D images that I upload on to forums, that structure, you should understand that was not possible work, because the rotor projecting too sharp, not only the room’s sealing cannot be guaranteed, and the normal rotation of the rotor cannot be guaranteed. There are a lot of problems you can see, after all, is a previous primary design! If you are interested in,Your views? email sky-hawk@126.com