Discussion Overview

The discussion centers around the application of the left-hand rule to determine the direction of force in a motor with a winding configuration. Participants explore the implications of current direction in various segments of the winding and how this affects the overall force and torque produced by the motor. The conversation includes theoretical considerations, practical observations, and references to specific motor designs.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

Main Points Raised

- One participant expresses confusion about the direction of force in a motor with multiple windings, questioning how to determine the principal force when currents may cancel out.

- Another participant suggests that if the winding has equal current and directions, the forces may cancel, leading to uncertainty about the principal force directions.

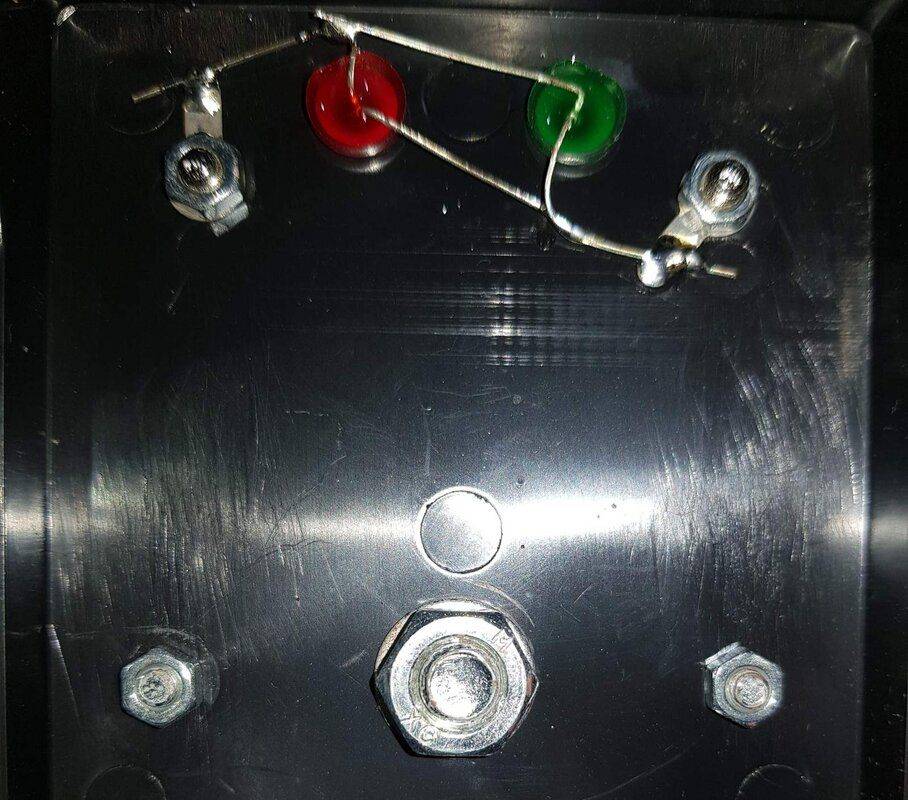

- Several participants discuss the behavior of currents in different segments of the winding (AB, CD, BC, AD) and how they interact with the magnetic field, noting that while currents may be equal in magnitude, they can be opposite in direction, affecting the resultant forces.

- One participant describes how to visualize the forces by imagining the rotor's position and the direction of current, suggesting that the rotor can be treated as an electromagnet.

- There are questions about the configuration of the motor's magnetic components, including whether the entire metal body acts as a magnet or if it is localized to specific areas.

- Another participant points out potential issues with the current direction in the motor, suggesting that reversing the current may be necessary for proper operation.

Areas of Agreement / Disagreement

Participants express differing views on the direction of forces and the behavior of currents in the winding. There is no consensus on the principal force direction or the implications of the winding configuration, indicating that the discussion remains unresolved.

Contextual Notes

Participants reference specific configurations and behaviors of currents and forces without reaching a definitive conclusion. The discussion includes assumptions about the motor's design and the effects of current direction that are not fully explored or resolved.