Missurunha

- 3

- 0

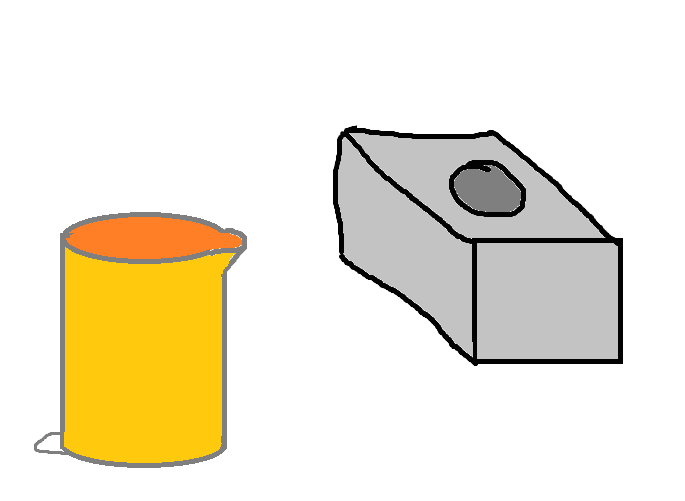

I'm trying something similar, it's a mechanism to lift/tilt a cylinder, in order to drop whatever is inside the cylinder into another box. (the substance cannot be pumped)

The cylinder is about 250kg heavy, and I'd have to lift it around 1,5m, then tilt it.

I'm afraid I can't lift it with chains, cause it may swing and leak part of my substance. (actually I can, but I'd like to hear some other suggestion)

A quick drawing:

For the tilting I would use a chain at the bottom, after the cylinder is lifted, the bottom would be pulled by this chain and tilt the cylinder.

The cylinder is about 250kg heavy, and I'd have to lift it around 1,5m, then tilt it.

I'm afraid I can't lift it with chains, cause it may swing and leak part of my substance. (actually I can, but I'd like to hear some other suggestion)

A quick drawing:

For the tilting I would use a chain at the bottom, after the cylinder is lifted, the bottom would be pulled by this chain and tilt the cylinder.