ca2n

- 10

- 0

Hello all,

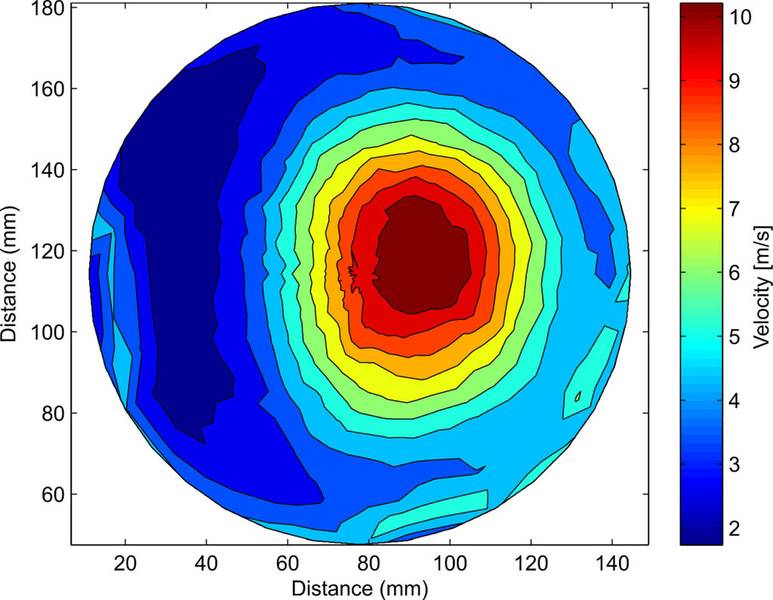

Looking for ideas on how to calculate mass flow rate from a velocity contour plot. The cross-sectional area is circular. An example of the velocity contour plot is shown in the figure below:

In most of the cases (as exemplified above) the flow is non-axisymmetric. Any suggestions welcomed. Thank you in advance.

Looking for ideas on how to calculate mass flow rate from a velocity contour plot. The cross-sectional area is circular. An example of the velocity contour plot is shown in the figure below:

In most of the cases (as exemplified above) the flow is non-axisymmetric. Any suggestions welcomed. Thank you in advance.