MechaMZ

- 127

- 0

Hi,

i hope someone can kindly give me some opinions for my idea :)

I've a project related to vortex induced vibration. The prototype has a cylinder submerging into moving fluid, and it generates a upward/ downward motion in cycles.

I want to measure the efficiency of my prototype, which energy can be extracted by my prototype from the moving fluid.

Due to prototype's limitation, it seems hard for me to install a small scale alternator to measure energy output. Thus, I've an idea to measure it by the spring movement. i.e. spring extension and compression.

the idea is:

https://www.physicsforums.com/attachment.php?attachmentid=39181&d=1316715663

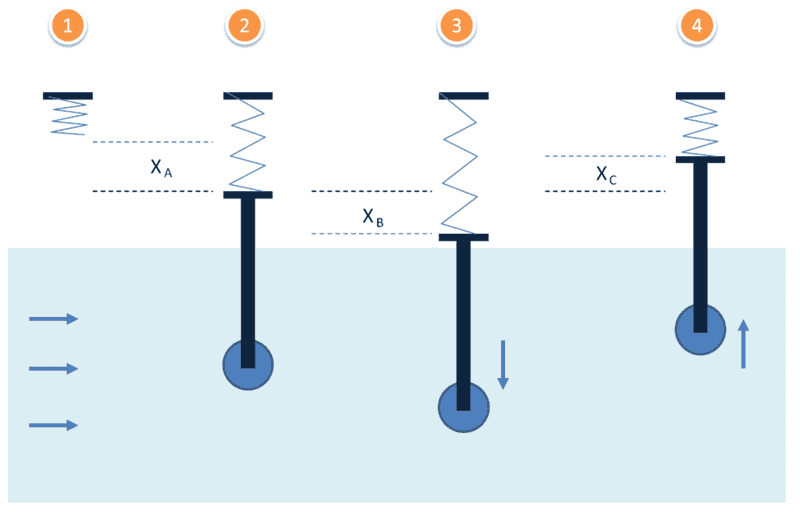

there are 4 phases of the spring, i.e.

(1) no load

(2) extended by cylinder and its supports, the cylinder is under equilibrium by spring force, bouncy force and weight.

(3) cylinder is moving downward by exerted force due to vortex, spring extended.

(4) cylinder is moving upward by exerted force due to vortex, spring compressed.

the cylinder is moving up and down continuously. my method is:

(1) let the energy extracted from moving fluid = total energy stored in the spring

(2) total energy stored in the spring = 0.5k(XB)2 + 0.5k(XC)2 - 0.5k(XA)2

here i only look into one cycle of motion. hope anyone could kindly enlighten me, thank you and appreciated!

i hope someone can kindly give me some opinions for my idea :)

I've a project related to vortex induced vibration. The prototype has a cylinder submerging into moving fluid, and it generates a upward/ downward motion in cycles.

I want to measure the efficiency of my prototype, which energy can be extracted by my prototype from the moving fluid.

Due to prototype's limitation, it seems hard for me to install a small scale alternator to measure energy output. Thus, I've an idea to measure it by the spring movement. i.e. spring extension and compression.

the idea is:

https://www.physicsforums.com/attachment.php?attachmentid=39181&d=1316715663

there are 4 phases of the spring, i.e.

(1) no load

(2) extended by cylinder and its supports, the cylinder is under equilibrium by spring force, bouncy force and weight.

(3) cylinder is moving downward by exerted force due to vortex, spring extended.

(4) cylinder is moving upward by exerted force due to vortex, spring compressed.

the cylinder is moving up and down continuously. my method is:

(1) let the energy extracted from moving fluid = total energy stored in the spring

(2) total energy stored in the spring = 0.5k(XB)2 + 0.5k(XC)2 - 0.5k(XA)2

here i only look into one cycle of motion. hope anyone could kindly enlighten me, thank you and appreciated!