- #1

Jameseyboy

- 25

- 1

Hi Guys,

I have been given a lab report to complete on Torsion of a beam.

- Beam was subjected to torsion under increments of weight

- Strain gauge rosette was placed, A B and C where there is 90 deg between A and C, B at 45 deg in between.

- The angle from Gauge A and the "x" axis was given as 28 deg

I have predicted a set of readings for A, B and C.

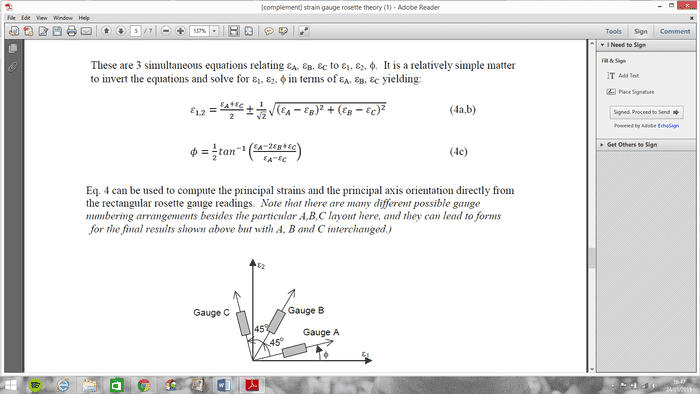

Now I have to construct a Mohr's circle from these values, relative to the shaft axis and find principal strains, principle direction and max sheer strain.

So far,

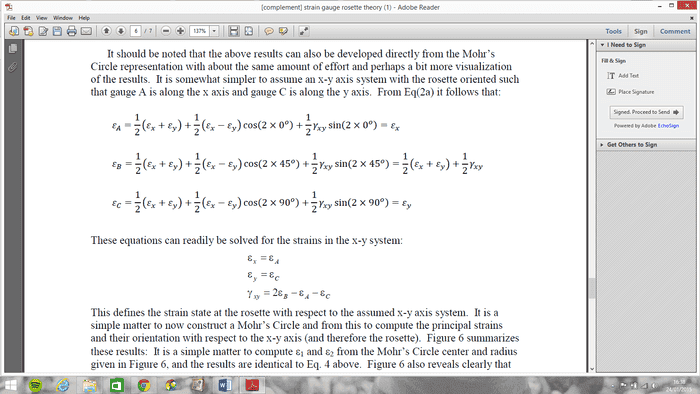

I used these to compute the strain readings to values for the mohrs circle.

Then, I used these to find the Principal Directions

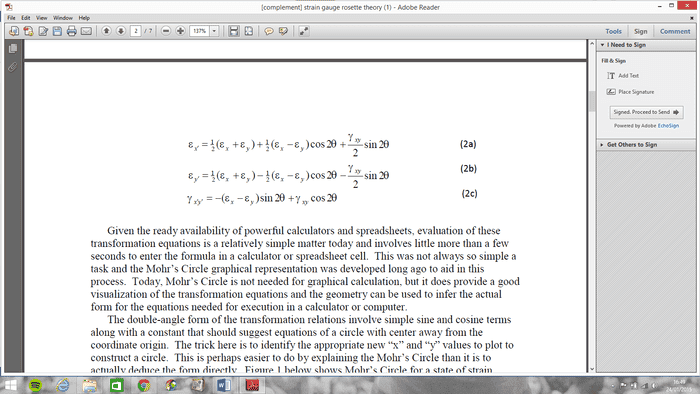

But then I am not sure how to use these equations for the ACTUAL orientation of the gauges/strains when I see these two

If anybody has any ideas, I would be eternally grateful. I have been to tutors but they have been particularly unhelpful.

If anyone prefers to PM or Skype just let me know and I can explain my work so far.

I have been given a lab report to complete on Torsion of a beam.

- Beam was subjected to torsion under increments of weight

- Strain gauge rosette was placed, A B and C where there is 90 deg between A and C, B at 45 deg in between.

- The angle from Gauge A and the "x" axis was given as 28 deg

I have predicted a set of readings for A, B and C.

Now I have to construct a Mohr's circle from these values, relative to the shaft axis and find principal strains, principle direction and max sheer strain.

So far,

I used these to compute the strain readings to values for the mohrs circle.

Then, I used these to find the Principal Directions

But then I am not sure how to use these equations for the ACTUAL orientation of the gauges/strains when I see these two

If anybody has any ideas, I would be eternally grateful. I have been to tutors but they have been particularly unhelpful.

If anyone prefers to PM or Skype just let me know and I can explain my work so far.