- #1

core7916

- 56

- 3

- TL;DR Summary

- why short between drain and source ?

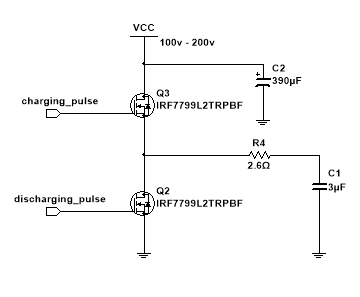

Hello, i am using a switching circuit with the power mosfets to actuate the piezo loads, but while working on this circuit, my mosfet is getting bad, means i am observing short between mosfet source and drain. ( happend in 4 mosfets)

i will attach the circuit daigram of my circuit.

switching frequency will be 10hz with 2ms charging and rest is discharging the 3uf capacitor (ref to load and have 200kohm resistance).

in circuit c1 ref to load. and all components are rated for more than 300v. (part numbers are different in real time circuit.)

what wrong with my circuit? and what to do to avoid the shorting of mosfets.

i will attach the circuit daigram of my circuit.

switching frequency will be 10hz with 2ms charging and rest is discharging the 3uf capacitor (ref to load and have 200kohm resistance).

in circuit c1 ref to load. and all components are rated for more than 300v. (part numbers are different in real time circuit.)

what wrong with my circuit? and what to do to avoid the shorting of mosfets.