fraggordon

- 1

- 0

- TL;DR

- Trying to solve pressure in branching pipes with non-equal diameters. Inlet flow parameters are given.

Electrical engineer here hi!

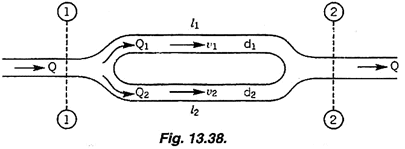

I'm little bit out of my comfort zone trying to figure out the following fluid mechanics problem. I have a branching pipe similar to schematic below...

...and I'm trying to find the pressures in branches 1 (p1) and 2 (p2). The d1 and d2 are not equal (d1 = 0.1*d and d2 = 0.5*d) but the lengths l1 and l2 are equal. The inlet diameter (d), flow rate (Q), velocity (v) and pressure (p) are given.

Is it even possible to figure out the p1 and p2 with this little information? If so, where should I start? I imagine that at least following equations will be needed, but I guess I would need something else as well?

1) Conservation of flow rate: Q = Q1 + Q2

2) Conservation of energy (no losses or height difference): 0.5*density*v^2 + p = 0.5*density*v1^2 + p1 + 0.5*density*v2^2 + p2

I'm little bit out of my comfort zone trying to figure out the following fluid mechanics problem. I have a branching pipe similar to schematic below...

...and I'm trying to find the pressures in branches 1 (p1) and 2 (p2). The d1 and d2 are not equal (d1 = 0.1*d and d2 = 0.5*d) but the lengths l1 and l2 are equal. The inlet diameter (d), flow rate (Q), velocity (v) and pressure (p) are given.

Is it even possible to figure out the p1 and p2 with this little information? If so, where should I start? I imagine that at least following equations will be needed, but I guess I would need something else as well?

1) Conservation of flow rate: Q = Q1 + Q2

2) Conservation of energy (no losses or height difference): 0.5*density*v^2 + p = 0.5*density*v1^2 + p1 + 0.5*density*v2^2 + p2