Discussion Overview

The discussion revolves around the intricacies of race car suspension design, particularly for stock cars and formula cars. Participants explore various technical aspects such as roll center, instant center, suspension geometry, and the effects of body roll on tire performance. The conversation includes both theoretical considerations and practical applications relevant to race car handling and performance.

Discussion Character

- Technical explanation

- Exploratory

- Mathematical reasoning

- Debate/contested

Main Points Raised

- One participant emphasizes the importance of understanding roll center height and its impact on weight distribution during cornering, noting that a lower roll center increases vertical loading on tires.

- Another participant discusses the need for body roll to effectively transfer weight to outside tire contact patches, suggesting that improper weight transfer can lead to loss of grip.

- Several participants propose various factors affecting suspension design, including kingpin inclination, scrub radius, camber, caster, and toe-out settings.

- There are discussions about the significance of instant center width and how it influences roll center behavior during body roll, with some suggesting that a narrow instant center width can lead to more radical changes in tire loading.

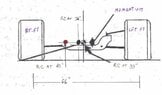

- One participant outlines a detailed approach to designing suspension mounting points, including specific measurements and angles that must be calculated to achieve desired performance characteristics.

- Another participant expresses interest in exploring wheel rates and spring selection in future discussions, indicating a desire for deeper technical insights.

Areas of Agreement / Disagreement

Participants generally agree on the importance of various suspension parameters and their effects on race car performance. However, there are multiple competing views on the optimal configurations and the implications of different design choices, leaving the discussion unresolved in certain areas.

Contextual Notes

Participants reference specific software tools and literature for suspension analysis, indicating that practical application may depend on access to these resources. Additionally, some discussions involve assumptions about vehicle design that may not apply universally across different race car types.