Omg999

- 2

- 0

Hi!

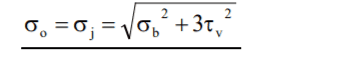

I need help with a task. I have done previous calculations on the shaft, but I'm stuck now, as I'm going to find out how many degrees the shaft is twisting from point C to D. I have calculated bending/shear stress, torsion stress and the last stress that i don't know in english, but the formula is like this:

So I am wondering if anyone has done this before?

I need help with a task. I have done previous calculations on the shaft, but I'm stuck now, as I'm going to find out how many degrees the shaft is twisting from point C to D. I have calculated bending/shear stress, torsion stress and the last stress that i don't know in english, but the formula is like this:

So I am wondering if anyone has done this before?