bartlino

- 3

- 0

- TL;DR

- how to create a function in Python to model an electric heating element heating a tank of water

there's a website to size an aquarium heater or chiller.

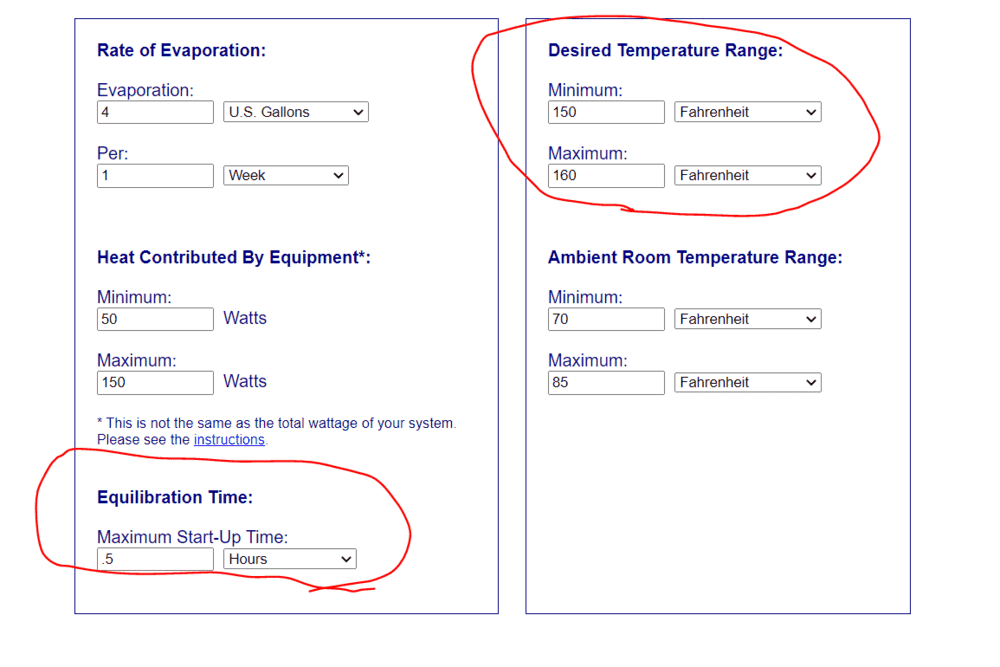

This is just for learning purposes (not for fish) but I have modified these parameters from default to perform a load calculation on a 100 gallon glass tank... For the tank temperature range I set to be between 150-160 degree F. and a startup time of .5 hours, all other parameters are left default...

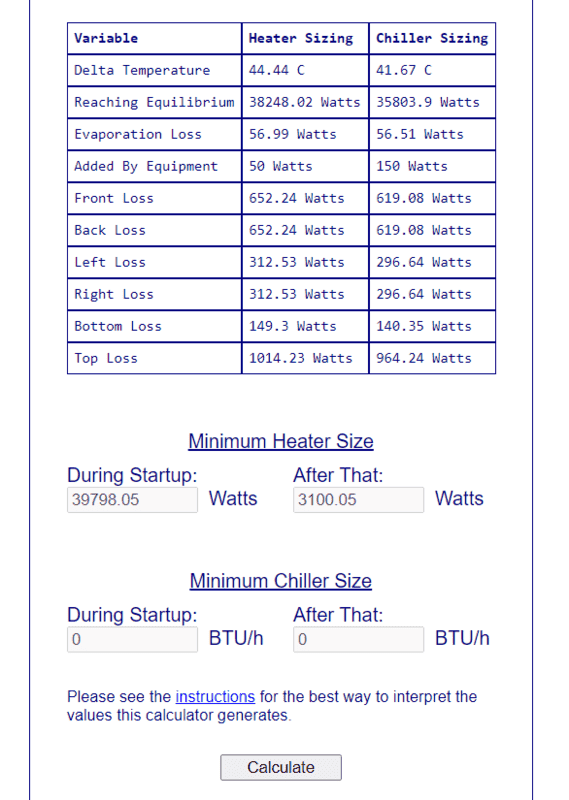

The load calc output looks like this to see all of the losses:

The question I have, is how I could I model the tank temperature over time of a 4000 watt heater cycling on and off to maintain a 150 degrees setpoint? IE, if the tank drops below 145F the heater would come on and then shut off when the tank temperature reaches 155F.

The question I have, is how I could I model the tank temperature over time of a 4000 watt heater cycling on and off to maintain a 150 degrees setpoint? IE, if the tank drops below 145F the heater would come on and then shut off when the tank temperature reaches 155F.

Using Python, I think I can calculate in hours how long it will take for the tank temperature to drop the 5F for when the heater would need to come on but would anyone have any tips for how I could model/calculate the tank temperature & burner cycling? (plot data over time..)

[CODE lang="python" title="Python script"]

tank_volume = 100

gall_pound_conversion = 8.33

drop_in_temp = 10 #btu per pound

btu_kwh_conversion = 3413

total_loss_evap_convection = 2692/1000 #divde by 1000 to convert watts to kW

def sim():

value = tank_volume * gall_pound_conversion

value = value * drop_in_temp

value = value / btu_kwh_conversion

value = value / total_loss_evap_convection

return valueprint(sim())

0.9066374569047897[/CODE]

printing the function (sim()) this yields 0.9066374569047897 which I think is in hours

This is just for learning purposes (not for fish) but I have modified these parameters from default to perform a load calculation on a 100 gallon glass tank... For the tank temperature range I set to be between 150-160 degree F. and a startup time of .5 hours, all other parameters are left default...

The load calc output looks like this to see all of the losses:

Using Python, I think I can calculate in hours how long it will take for the tank temperature to drop the 5F for when the heater would need to come on but would anyone have any tips for how I could model/calculate the tank temperature & burner cycling? (plot data over time..)

[CODE lang="python" title="Python script"]

tank_volume = 100

gall_pound_conversion = 8.33

drop_in_temp = 10 #btu per pound

btu_kwh_conversion = 3413

total_loss_evap_convection = 2692/1000 #divde by 1000 to convert watts to kW

def sim():

value = tank_volume * gall_pound_conversion

value = value * drop_in_temp

value = value / btu_kwh_conversion

value = value / total_loss_evap_convection

return valueprint(sim())

0.9066374569047897[/CODE]

printing the function (sim()) this yields 0.9066374569047897 which I think is in hours

Last edited by a moderator: