Bart van Driessche

- 3

- 0

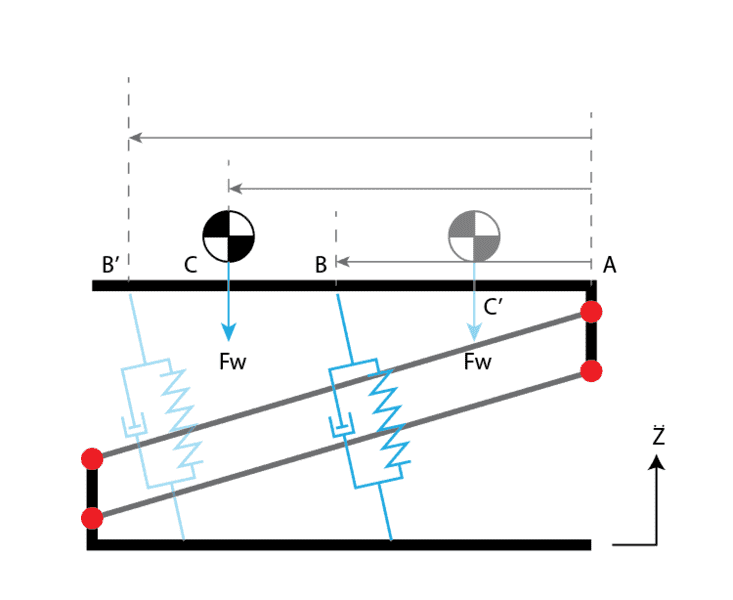

For my thesis at the department of Industrial Design Engineering, I am developing a suspension pedestal. These kind of products are used regularly in boats (link) or truck seats and make use of two diagonal beams and a shock absorber. The vertical excitation can originates from waves or road undulations. A simple FBD can be found below.

I was wondering if the location of the shock absorber, relative to the rear pivot points (A), affects the functioning/effectiveness of the system? If I am correct, placing the shock absorber more forward or backwards only puts more or less stress on the rear pivot points. Yet, by using proper bushings this may not affect the functioning/effectiveness of the system. Assuming the construction is stiff enough to withstand the weight (Fw).

Or, is it better to decrease the distance between the center of gravity (C), in relation to the rear pivot points (A)? E.g. placing the center of gravity at location C'.

Or, e.g., placing the shock absorber more forward at location B', so that the center of gravity (C) is located between point A and B'?

I was wondering if the location of the shock absorber, relative to the rear pivot points (A), affects the functioning/effectiveness of the system? If I am correct, placing the shock absorber more forward or backwards only puts more or less stress on the rear pivot points. Yet, by using proper bushings this may not affect the functioning/effectiveness of the system. Assuming the construction is stiff enough to withstand the weight (Fw).

Or, is it better to decrease the distance between the center of gravity (C), in relation to the rear pivot points (A)? E.g. placing the center of gravity at location C'.

Or, e.g., placing the shock absorber more forward at location B', so that the center of gravity (C) is located between point A and B'?