- #1

gregory112

- 11

- 3

- TL;DR Summary

- I am building a homemade VdG machine, and it does not generate any charges.

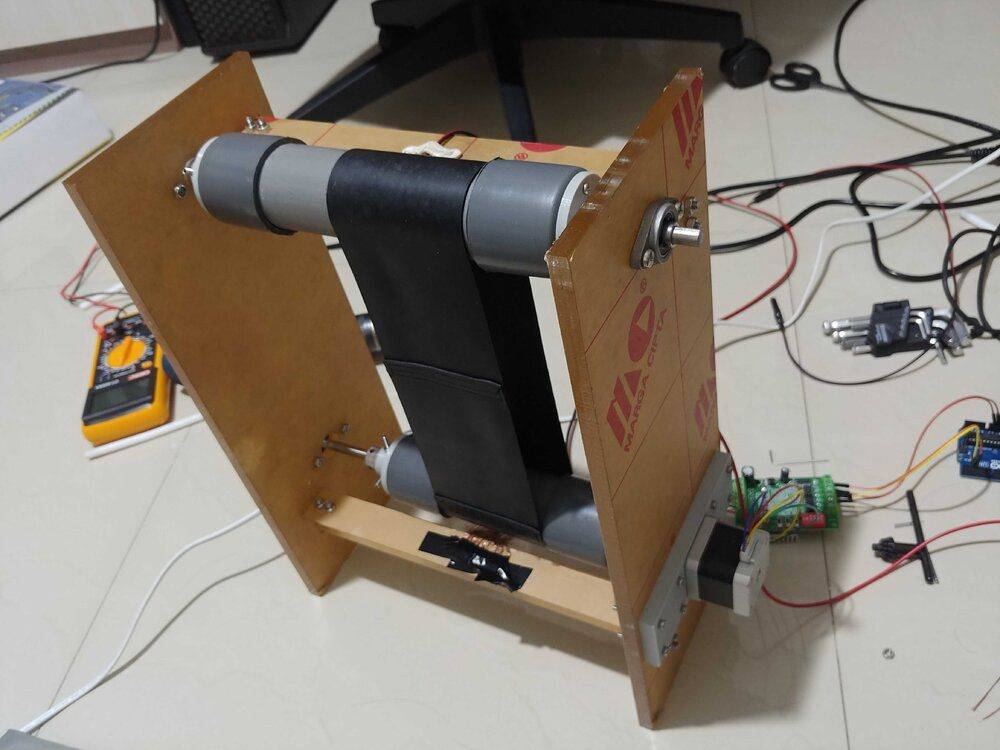

I'm trying to build a Van de Graaff generator, but it does not generate any charges.

The problem is, I don't know which part is accidentally shorted, or grounded. I use both PVC pipes for the top and bottom rollers. The belt is neoprene rubber, 1mm thick. The rollers are bolted on aluminum shafts, one aluminum shaft is connected to the motor (is this okay? maybe it's shorting it?).

My room hygrometer says it's 67% humid.

The shafts are attached on bearings on standing acrylic boards. I made combs from copper wires. I want to test whether this is a humidity problem, maybe grounding problem, or something else? I can rub the PVC and it picks up some pieces of paper just fine.

The dome is cylindrical, with flat sides, made from steel plates and pipes that are welded cut open. In the picture here I haven't attached the dome. Can someone help by pointing me to the right direction? I don't have a high voltage ammeter, can I just use a normal multimeter?

Before I attached the dome, I tried to make a leyden jar and connect one terminal (the ball on top of the jar) to upper comb, and the ground terminal (the body) to the bottom comb. The jar does not seem to be charged however.

The problem is, I don't know which part is accidentally shorted, or grounded. I use both PVC pipes for the top and bottom rollers. The belt is neoprene rubber, 1mm thick. The rollers are bolted on aluminum shafts, one aluminum shaft is connected to the motor (is this okay? maybe it's shorting it?).

My room hygrometer says it's 67% humid.

The shafts are attached on bearings on standing acrylic boards. I made combs from copper wires. I want to test whether this is a humidity problem, maybe grounding problem, or something else? I can rub the PVC and it picks up some pieces of paper just fine.

The dome is cylindrical, with flat sides, made from steel plates and pipes that are welded cut open. In the picture here I haven't attached the dome. Can someone help by pointing me to the right direction? I don't have a high voltage ammeter, can I just use a normal multimeter?

Before I attached the dome, I tried to make a leyden jar and connect one terminal (the ball on top of the jar) to upper comb, and the ground terminal (the body) to the bottom comb. The jar does not seem to be charged however.