SUMMARY

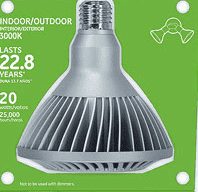

The metal fin-like structures on LED bulbs serve as cooling fins essential for maintaining optimal performance and longevity. Unlike incandescent bulbs, which operate efficiently at high temperatures, LEDs generate excess heat that can reduce light output and lifespan. Effective heat dissipation through these fins prevents overheating, ensuring that the LED operates efficiently and prolongs its life. The discussion highlights the importance of heat sinks in LED design, particularly for high-wattage applications where efficient thermal management is critical.

PREREQUISITES

- Understanding of LED technology and its thermal dynamics

- Knowledge of heat sink design principles

- Familiarity with semiconductor behavior under varying temperatures

- Basic concepts of thermal radiation and heat transfer mechanisms

NEXT STEPS

- Research LED thermal management techniques and best practices

- Explore the design and materials used in heat sinks for LED applications

- Learn about the impact of temperature on semiconductor performance

- Investigate alternative cooling methods for LEDs in high-altitude or vacuum environments

USEFUL FOR

Engineers, product designers, and anyone involved in the development or optimization of LED lighting solutions will benefit from this discussion.