ChristianMay21

- 1

- 0

Background: I'm a high school robotics team member.

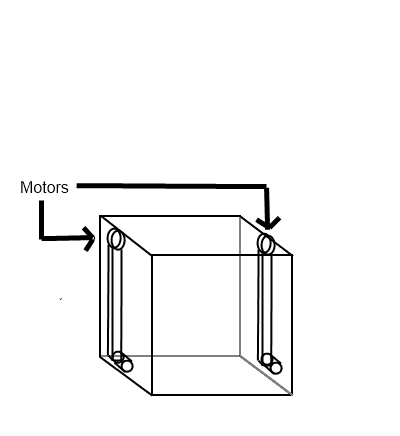

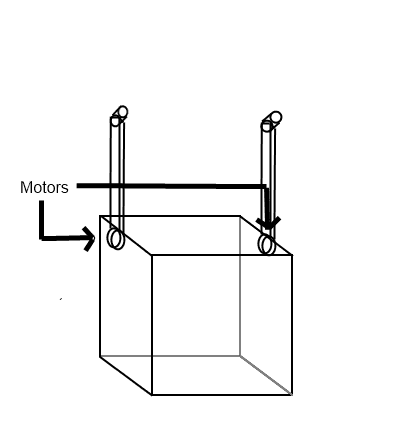

These first two images show the general design of the robot; the design is intended to use two arms, with "hooks" on the end (more like a bearing on a shaft, really), represented by cylinders, to hook onto a steel bar, and pull itself up, using the force from the motors.

This is shown by these images.

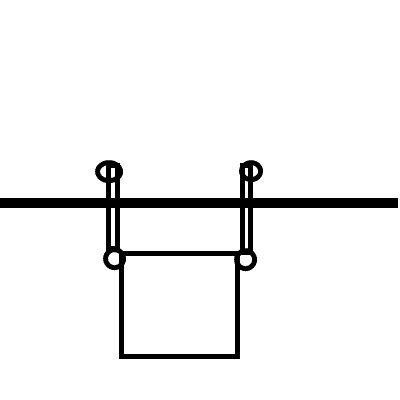

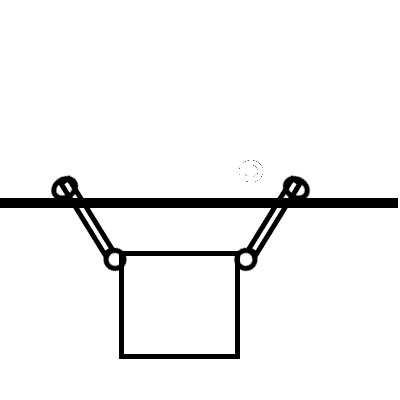

After the arms start pushing on the bar, the robot should begin to lift itself. The question is, given a motor on the joint with known torque, what is the force applied to the bar/weight that one can lift? Does it change with degrees? I'm familiar with physical terms so don't worry about dumbing it down. I just really really need an equation to relate these two XD The ones I've used seem to imply that the arm will exert zero force at some angles, which wouldn't make sense. Distance of the arm is known, also.

Thank you so much for your help!

These first two images show the general design of the robot; the design is intended to use two arms, with "hooks" on the end (more like a bearing on a shaft, really), represented by cylinders, to hook onto a steel bar, and pull itself up, using the force from the motors.

This is shown by these images.

After the arms start pushing on the bar, the robot should begin to lift itself. The question is, given a motor on the joint with known torque, what is the force applied to the bar/weight that one can lift? Does it change with degrees? I'm familiar with physical terms so don't worry about dumbing it down. I just really really need an equation to relate these two XD The ones I've used seem to imply that the arm will exert zero force at some angles, which wouldn't make sense. Distance of the arm is known, also.

Thank you so much for your help!