- #1

gary350

- 253

- 52

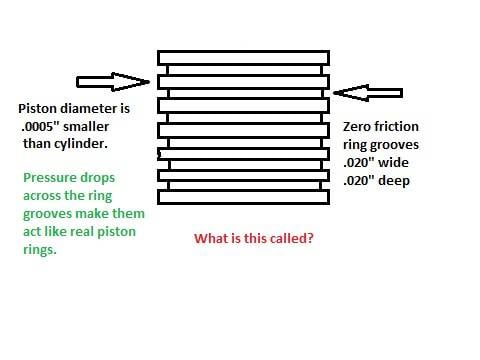

I learned this in college too. I once know the name of these zero friction piston rings but I have forgot. If I knew the name I could do Google search and learn more about them. College professor said, grooves are .020" wide and .020" deep. Pressure drop across the grooves make them act like real piston rings. I put these grooves on all my sterling engine pistons it is hard to tell how well they work sterling engines do seem to have more power and run better.

.

.