Nabil

- 2

- 0

Hi everyone,

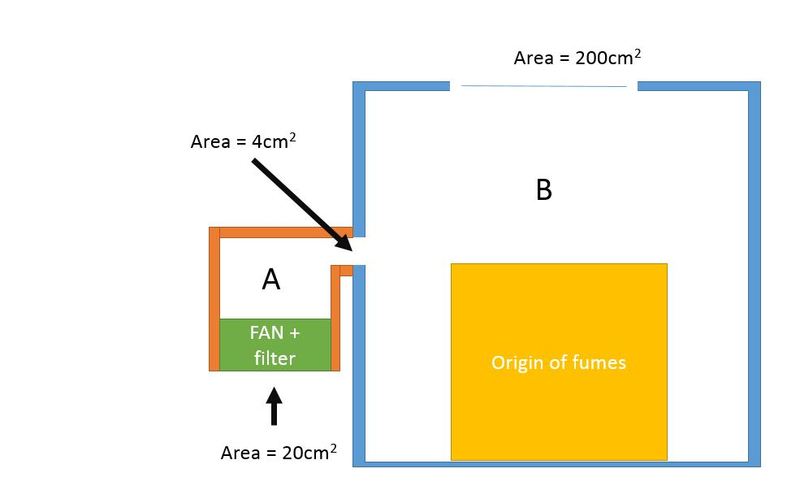

I've got a newbie question which is probably more complex than I imagine so please bare with me. As a small DIY project I've trying to build a small exhaust filter system (A) for another device that produces undesirable fumes (B). I'm trying to work out if an axial fan (generates greater air flow) or a centrifugal fan (more air pressure) would be better.

The setup

Ideally I would like to be able simulate the effect of different extraction rates will have on the air flow in Device B. And considering picking up a solid works 30 day trail package to run some simulations. But for now to I've been trying to figure out what kind of fan would work best for my setup. My two considerations are:

Any suggestions / advice would be most appreciated!

- Nabil

I've got a newbie question which is probably more complex than I imagine so please bare with me. As a small DIY project I've trying to build a small exhaust filter system (A) for another device that produces undesirable fumes (B). I'm trying to work out if an axial fan (generates greater air flow) or a centrifugal fan (more air pressure) would be better.

The setup

- The exhaust (A) is connected to an inlet on the device (B) with an opening of an area of 4cm2. the outlet for A has an area of 20cm2

- Device B besides the small 4cm2 outlet has an opening on the top with an area of appox 200 cm2. It is otherwise a closed environment. It has a volume of approx 60,000 cm3 or 0.06 m3

- Environment has normal room temp of 21c and normal atmos. pressure.

Ideally I would like to be able simulate the effect of different extraction rates will have on the air flow in Device B. And considering picking up a solid works 30 day trail package to run some simulations. But for now to I've been trying to figure out what kind of fan would work best for my setup. My two considerations are:

- An axial fan rated flow rate of 18 CFM (0.514 m3/min) and max + air pressure of 0.12 inH2O (3.04 mmH20).

- A centrifugal fan rated flow rate of 4.5 CFM (0.12 m3/min) and max + air pressure of 0.39 inH2O (7.85 mmH20).

Any suggestions / advice would be most appreciated!

- Nabil